|

|

|

|

Tabernaculum in the Szt László Church

|

|

|

|

|

Zinc Silicate Crystalline Glaze Pottery

Ferenc Halmos ......Biography

Crystalline Glaze.........Notes

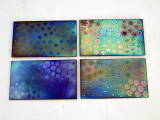

Matt Crystalline Glaze

These contain 2 types of crystals. Macro crystals which give a decorative effect and micro crystals which cover the full glaze surface and give a nice shine and are smooth to the touch.

Eosin Glaze.....Notes......Work For Sale

|

|

|

|

|

|

|

|

|

|

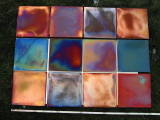

Copper Matt Raku

These are made using a special firing method - a modern version of the original Japanese raku technique . In this low-fire process bisqued work is quickly heated to 1000-1050°C, removed from the kiln with tongs and placed in a can lined with wood shavings, newspaper, leaves or a similar combustible material. As the can is covered, the combustible material produces a reduction atmosphere which causes the special glaze covering the piece of clay to turn into colors of the rainbow. These Copper Matt glazes produce fiery colors and velvety surfaces due to their high copper oxide content. The non-glazed clay turns grey or black after raku firing. This technique requires special attention and expertise. Due to the firing technique each and every piece is unique with a combination of colors and patterns that cannot be reproduced.

Furnaces........Methods

|

|

|

|

|

|

|

|

To isolate a kiln with 2 1\2 " brick is a wasting of energie. I have 6 selfmade kilns all of them for special purposes. I make allways very thick kiln walls. I send you 2 kiln photos. The smaller one is 20x19x28 inch, 11 KW heated with full power to seger cone 7 with 18pc 10 " vases in 3 and half hours. With 10 KW it is possible to firing it 1 hours longer. The other is a carkiln 40x44x27 inch 18 KW, with one layer of vases,heated to the same temp in 7and half hours.>

My kilns are isolated with 4 inch fiber and 4 inch ytong (on the cool

site)and works perfectly - At top temperature the outer sufrace is still cool. .

Heating elements are on Al oxid tubes. The roof I made as the follows: 1\3 inch

thick SiC plate, 4 inch fiber ( kaowool 1260 C grad type ) and 4 inch rockwool

on the cool site. 11 KW , 4 cub foot ,3-4 hours to seger cone 7.The door is on

the front site. ( I hate the toploaders: uncomfortable to pack them.)

> >

> > SK7 =1230 C(2246 F) OK 10= 1300 C (2380 F)

> >

> > The firing schedule of the 3rd yellow-blue vase (2410) :

> >

> > 5 min hold at peak temp 1230 C

> > cooling to 1070

> > cooling to 1010 with 20 C \ h

> > heating to 1070 with 40 C \hour

> >

> > Total firing time : 12.10 hours

> >

> > Ferenc

> >

:

The elements in my special selfmade electric kiln works wonderfool without

any damagas since circa 5-6 years.Its likes new. This is a simple kiln, but

completli isolated from air (with inox sheets is boxed)

The heating elements are on AL oxide pipes. CrAl type (alike to A1 Kanthal

but cost only cc half)

The firing temperature is law inough to not damaging the heating elements.

250-300 firings at cone7(1230 C grad ) + 300 firings at 1000 C grad. The heating

elements are made from "Aluchrom 0 "(the same quality as A1 Kanthal ), and its

surface load is about 1.5 W \ cm2

I propose you to try not only the usual "normal" recipes. When I start to create new special glazes I always try out extrem compositions at first. After that I refine step-by step my recipes. If I were You, I were change a part (or the all) of Your fritt to other melting materials (other fritts,Li, Na ,K ,Ca, Sr, Ba, P,B, ....compounds )

The crystallglazes are very sensitiv to the firing curves. Let You try Extremitys too ! The color of the reduction fired glaze will change with the changing firing curves. It is possible to reduction firing with gas in a gaskiln or in a electric kiln. The reduction with flammable solid and liquid materials gives different colors too. The vases in photobucket : red cryst 2 no 51(on the right side) and the red cryst 1 no 26(on the left) are the same.The fist was reduced with gas the other with wood. You can change the temp, the time of reduction. Refirings before and after the reduction gives new colors too.