|

Phil Hamling 376 County Route 1 Warwick, NY, USA 10990 |

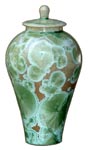

Zinc Silicate Crystalline Glaze Pottery A chronicle of my recent progress and a way for me to keep it straight in my head! Click on thumbnails to enlarge photos |

Info I've been asked to keep in confidence. | ||

|

| ||||

September 27, 2007 33rd Firing Results

September 25, 2007 33rd Firing Setup

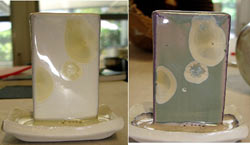

New elements? Nah! Change the hold time? Nah! Change the glaze? Nah! Well I did put a glossy white liner in a few of the pieces. Other than that I'm trying exactly the same thing I did in the last firing with the same glaze that was on the bowls. I'm curious to see if I can get the same effects and if the elements age more and cone 11 goes down further.

September 20, 2007

September 15, 2007 Photos from Krystallos 2007

Being at Krystallos 2007 was like a dream come true for me. I can't thank all of you enough for the warm camaraderie I felt. Although I never met anyone before this event, at the first night's dinner I felt like I could go up to half of you and say hello on a first name basis. It was great. The next 2 days events were amazing too (not to mention Jamie Kozlowski's shadow puppets.) I really didn't have much time to take many pictures though. I didn't want to miss anything. I did get some, but William and John and the rest of you, I can't believe I didn't get your picture!

Photos from Krystallos 2007 at Bill Campbell's

September 11, 2007 32nd Firing Results

|

|

| |

|

Never Forget! | |||

|

|

|

|

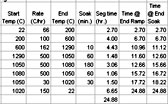

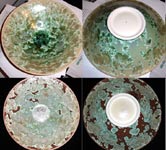

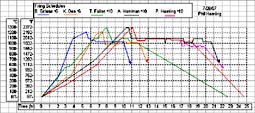

I changed the firing cycle to go directly into a 3 hour soak at 1080°C followed by 5 successive 10 minute long ramps to 1000°C with a ten minute hold then a 10 minute ramp back up to 1080°C with a 10 minute hold. Some of these pieces have a real psycho look where the 5 rings run between small crystals that started part way through the first hold.

This time I added a cone 11 to the mix to see just how much past cone 10 my aging elements were going. It looks like I got all of cone 11. It seemed to help the over nucleation situation but the crystals are not as large as they've been in the past. The puzzler is how far do I go. Should I run them to failure? Run the risk of way over firing and ruining a load?

The pot pictured in the lower left corner above (light brown background with silver blue crystals) is made of Fallon Classic clay. It had zincite seeds pressed into the leather hard body. It seemed to work OK, but I was surprised how much they ran. I tried to pick small pieces.

September 10, 2007

|

Diamond hand lap used to remove zincite seed protruding from the surface of the piece. With just a few strokes and light hand pressure they are quickly smoothed down. |

September 9, 2007 32nd Firing Setup

September 8, 2007 31st Firing Results

|

|

|

|

These pieces are made using 2 clays, Tucker's 10-85 Translucent Porcelain and H.H.P. Porcelain. There seems to be little difference between these 2 clays. Both show very little back ground with the uncolored glaze. The pieces with the most copper carbonate have the most background and those with an intermediate level have an intermediate amount of background. There is a large difference between the nucleation rate from these 2 clays and that from the 2 grolleg based porcelains I've used (Standard Clay Co. Grolleg Porcelain and Miller 550 by Laguna Clay Co.) I have some pieces made of these 2 plus Fallon Classic almost ready to glaze.

I plan to add more glaze containing a higher level of copper carbonate to some of them and refire tonight. There should be some interesting raku effects in the copper pieces.

The revised firing schedule had an effect in that I can see a repeat of three ring sequences at the low end, but it is too subtle. I plan to raise these lower holds and slow the transition between soaks.

September 6, 2007 31st Firing Setup

This is the last batch of bottles Chris Groat threw before heading off to medical school. They are glazed with 8% rutile base, 8% titania base with 2% copper carbonate and a mixture of the two. It will be nice to get a few pieces for raku at Krystallos 2007 next weekend.

I am using the 16 segment program as defined below except the lower 3X repeating sequence of hold temperatures have been raised from 954°C & 925°C to 1000°C & 975°C. I hope my elements have enough life life left in them to go through the cycle OK. I haven't seen any change in performance as evidenced by cones yet, but the elements themselves are starting to look beat up.

September 3, 2007

I haven't fired anything in over 2 weeks! It's making me buggy. I finally got Chris' bottles wet sanded and ready to glue to glaze catchers. I'm trying to get some pieces glazed and ready for Jesse Hull's Raku at Krystallos 2007 in addition to just getting something going. The last of the latest glaze catchers and a few new pieces are in bisque fire tonight.

My new initials stamp turned out OK. I machined 2 of them (0.65" dia. & 0.75" dia.) on one of the CNC routers at ZIRCAR. It gives detail I couldn't get with my hand carved one.

August 26, 2007

|

A bowl by Chris Groat with 3% CuCO3 in 8% titania base before (above) and after (below) post fire reduction by Terry Fallon. |

|

|

|

I wore a chunk off my right middle fingernail throwing all this stuff. I need an alternate technique.

August 25, 2007 I threw about 25 glaze catchers in a little over an hour using my new favorite tool (see below). I should be a glazing fool pretty soon.

August 20, 2007 2 Lids.

|

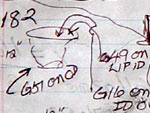

Where did that angle come from 1/4 of the way up the pot? |

August 18, 2007 A little help from John Tilton (Dialogue)

I tried and think it helped, except I missed the part about the widest point of the pot being about 2 inches below where it is now.

August 16, 2007 L&L Kin uniformity tests, ^05, Fast Bisque

August 15, 2007

August 13, 2007 30th Firing Results

August 12, 2007 30th Firing Setup

Next Day Observations

I saw it flip over into User 6. When User 5 was complete the controller seemed to hesitate and then displayed "On". I saw the temperature rise to 1025C, hold for 10 minutes then drop to 950C. It took 18 minutes , a rate of ~335C / hr.

I finally go to glazing the lidded pieces that seem like they've been around for ever. Two pieces have 2% copper carbonate in the 8% titania base. The other is a 50 - 50 mix of this and the 8% rutile base. Chris Groat's chalice is all rutile base. I seeded all the pieces and increased the soak at top temperature to 15 minutes.

|

|

|

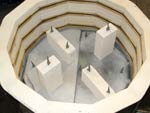

| Quite an array of "stuff", making for a tight load. | This is the debut of my use of the Fallon Stilt method. | It's only ~1/2 as densely packed as the kilns I saw Fa load. |

William,

Sometimes I don't think I'm smarter than a 5th grader. After reviewing the rings form the last firing I see I didn't get 16 segments - only 8 (even though I said I did.) I'm hoping it's because the soak temperature of first segment of "User 6" (975°C) was set to less than the ending temperature of "User 5" (1000°C) as you cautioned. I changed it to go up to 1025°C. Keep your fingers crossed.

|

I didn't get the 16 segments as I originally thought - only 8. |

"Bella" joined the family this weekend. |

August 8, 2007 Before and After, Thanks to Terry and the JMH-5F Reductionator

Two pieces from the 28th firing which Terry put through the new electric post fire reduction paces. Both have the same glazes. 8% rutile base with 2% CuCO3 on the outside and 8% rutile base on the inside.

August 7, 2007 29th Firing Results

I think I had 2 very nice pieces come from this firing including the first of Chris Groat's bowls (with a pinhole in the bottom) and a piece with Fa's Celestite (sp?) with nickel glaze from the workshop over red stain. The hole let a lot of glaze through the bottom of the bowl and seemed to leave just the right amount for Wild Williamesque needles to grow and the higher firing thinned the crystal herd allowing more of the red stain to peek through.

|

William, The 3 cones came out within a fraction of each other. Notice on the top one I scr*w*d up an put ^9 behind ^10. |

The workshop dog with 5% barium improved after refire with a layer of titania base w/ 4% MnO2. The one with 5% erbium did not. |

The next time I fire nickel over red stain I will soak longer to show more background. Maybe an additional 20 minutes will do it. |

The 16 seg. firing did happen. I got more low end rings, but they don't repeat 3X. I guess the holds were too low and growth stopped so the cycle didn't start back up. |

New L&L Kilns being installed at work.

An interesting Article....Fluorescent Glazes

August 5, 2007 29th Firing Setup

Re-firing 2 pieces from the workshop that had no crystals*, a piece with nickel over red stain (like the one below except I'm hoping for more background as Fa only fired at a rate of 9999 to 2300°F / 1260°C - I never saw cones) plus one of Chris Groat's bowls with 3% CuCO3. I'm trying to use the 16 segment cycle again (for the first time successfully - see July 28.) to get the white, black and brown rings at the low end with copper.

*All right! One puny little crystal.

August 3 - 5, 2007 "Mastering Crystalline Glazes" Workshop with Fara Shimbo at Wesleyan Potters

What a great facility and wonderful people! Its like a pottery country club. I would recommend a workshop here to anyone.

July 29, 2007 My New Favorite Tool

I came up with this tool to help make glaze catchers exactly the size I want with well formed top and side surfaces. It turned out to be simple to adjust and use.

|

|

|

|

|

A combo of 304 and 8-18 Stainless Steel. |

Set the length to exactly the right size. |

Form the catcher to the rough size. |

Shape the top and sides while matching the diameter. |

July 29, 2007 28th Firing Results

I must have blown it because the firing did not link to the second program to give 16 segments. It simply shut off and crash cooled. I'll have to be more careful next time and make it happen when I can be near by during the transition. No psycho rings this time! Hopefully next time!

More results from the Fallonator

July 28, 2007 28th Firing Setup

Included are 2 pieces with 3% CuCO3 for the Fallonator, 1 lidded piece with 4% MnO2 And Kat's Whachamacallit.

I finally took the time to read the controller manual to figure out how to link to programs and get 16 segments. This firing includes a series of low ramps and holds in an attempt to get some Mankameyer / Fallonesque Psycho Rings!

July 22, 2007 27th Firing Results

July 21, 2007 27th Firing Setup

|

Three more pieces made of Fallon§Classic clay. Two with 2% Nd2O3 in the 8% titania base and the last with 8% rutile base. They should light up purple and gold in the Fallonator. |

26th Firing Results

|

|

|

|

|

|

|

|

|

|

|

|

July 20th 550°C Sneak Preview.

|

I know I'm a bad, bad, bad, bad boy, but I couldn't resist. I got paid back with a really lousy photo. I guess I was too afraid to hold it open long enough to let my camera focus. |

July 19, 2007 26th Firing Setup

Chris' goblet is glazed with 4% MnO2 colored (non-crystalline) liner glaze on the stem, with 2% MnO2 + 1/2% CoCO3 colored titania base on the top. I have it placed, without a catcher, on a piece of alumina fiber insulation (just in case.)

July 17, 2007 25th Firing Results

The fibrous insulation I used for the temporary lid is just too good an insulator. The kiln was way too hot to unload, or even get a sneak preview shot last night. It was still pretty warm this morning. I'll have to learn to be patient, or when to crack the lid.

|

|

|

July 15, 2007 25th Firing Setup

Today I finally got a firing loaded. And a heavy one at that. I finally got to glaze the 2 tall vases, Chris Groat sent a long time ago (with rutile base) and a lidded piece I made in 1979. I hope they come out OK and there is enough time for him to do the Reductionator thing before heading off to medical school. The results should be interesting.

|

|

|

My last firing was 29 days ago. It's felt like withdrawal. In addition to the non-crystalline glaze activities spotlighted below we had my son's high school graduation party last night. Fortunately everyone and most things came through intact.

Electric Reduction Kiln Update

July 11, 2007 Post fire "light" reduction by Terry§Fallon. "Before: (fired in oxydation) on the left and "After" (fired in light reduction) on the right.

|

|

|

July 8, 2007

|

|

|

| Test tiles of Fallon§Classic | Chris' Bowls |

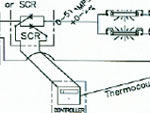

Electric Reduction Kiln?

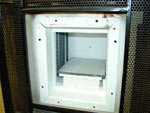

I built this unit in ~1982, It uses 8 Spiral Groove SiC elements (I2R Type SER), platinum t.c., low density alumina fiber insulation, runs on a 120V, 20 amp circuit and has been operating as high as 1500°C (2732°F) I think this system will be useful in an electric reduction kiln as the manufacturer's literature says they are rated to 2500°F in hydrogen). This unit is a little on the small side, as it was built as an R&D test kiln. A bigger unit would be no problem.

|

|

|

A New Army of Test Soldiers

I applied 20% inclusion stain containing engobe to 17 pieces to help get a better handle on what it takes to make them all give nice crystals (hopefully).

|

6-30-07 More Fish Scales |

July 4, 2007 Golf Green Repair |

July 6, 2007 Our front yard made the local paper | |

|

. |

|||

PS: I know this is off topic but it is what's keeping me from more crystalline glaze work.

http://www.stlawrenceriverfishingcharters.com/dinner.html

6-26-07

I probably won't put any new photos up for ~ 2 weeks. I am going to the Thousand Islands fishing this weekend and am not sure about next weekend.

I have been amazed at how many visits this page has gotten. My estimate is 40 per day. I guess other people are as intoxicated by crystalline glazes as I am. Now it is 10:18pm NY time and the hit counter says 5090.

6-18-07 24th Firing Results

6-17-07 24th Firing Sneak Preview (Avril, It was at 220°C, I couldn't resist and tried to move quickly!)

x

More reduction magic by Chris Groat. He reduced the bowls from the 20th firing.

x

6-16-07 24th Firing Setup

23rd Firing Results

6-15-07 22nd Firing Results (450°C Sneak Preview) and 23rd Firing

I decided to fire these again for a third time without any additional glaze and increased the top end hold from 10 to 30 minutes.

6-14-07 22nd Firing

Avril Farley wrote: "I'd like to see the result you try refiring one plate and the over seeded inclusion nickel with no additional glaze and nothing else in the kiln. " Here goes!

6-14-07 21st Firing Results

Let me deal with the good first!!!!! The 1% NiO in 1% titania glaze looks good on the small bowl made of "Unknown" clay. The (few) crystals on the Laguna 550 clay have an interesting shape and orientation (no seeding). Other than that I have to say the results of this firing are disappointing. I think I did jinx myself by crowing about how the 8% rutile base is fool proof. It fish scaled!

The inclusion stained piece is a total bust. It must be the rutile that made the previous piece tick!!!!

|

|

|

|

21st Firing

I think I made a big boo boo! As I was walking away after pressing the start button I realized I had mixed the nickel oxide glaze using 1% titania rather than 1% rutile. I had my fingers crossed that it wouldn't make a difference. I think I see it makes a big difference on the inclusion stained piece. Rather than looking like the piece from my 18th firing, this piece has the over nucleated microcrystalline look I've seen on test tiles before.

| 6-12-07 | 6-13-07 | |

| Setup | 700°C Sneak Preview | |

|

Chris' large plates on bottom shelves with 8% rutile base on top, white liner on bottom. The pieces on the top shelf are all glazed with 1% Green NiO in 1% titania base. |

Nickel on 4 different clays. 11:00 and 4:00: Laguna 550, 1:00 Inclusion Stained Tucker's HHP, 6:00 Highwater P-10 & 9:00 Unknown | |

6-12-07 20th Firing Results

6-11-07 Preview "Let's Make a Deal" Bowls

|

Fish scales on top. |

A little bit of background showing on the rim. |

Nice crystals on the outside. |

Yellowish P-10 porcelain tall vases and plate*. |

*Chris, It looks like P-10 has something leaching out while drying. Notice the yellowish color? I wonder if that has something to do with it making fish scales. I wonder what the vases will do with nickel?

6-10-07 20th Firing Setup

6-7-07 19th Firing

6-3-07 18th Firing Results

6-2-07 18th Firing

5-31-07 More pieces reduced by Chris Groat

|

3% CuCO3 in 8% rutile base. |

This has to be the ugliest thing I've ever made! |

Nd2O3 in rutile base. |

|

See 5-17-07 for "before" |

See 5-23-07 for "before" | |

5-25-07

5-24-07 A night off

5-23-07 17th Firing Results

5-22-07 Sneak Preview 250°C

5-21-07 17th Firing Setup

|

|

|

|

| Attempted seeding before refiring | Refires coated with light glaze application with CMC | Test tiles: titania and rutile bases with 2% Nd2O3 and 1/2% Fe2O3 | "Texas Style" crystals |

I didn't particularly care for the way the 2 pieces with 2% NiO, 1/4% CoCO3 came out. The background is kind of bland and there are very few crystals. I tried to seed them by Dremelling slits in the surface and filling them with 50/50 ZnO2 / SiO2 paste. I overglazed with the same glaze after adding CMC and 1/2% Fe2O3.

5-21-07 16th Firing Results

|

|

|

|

|

A range of colorants |

This piece is on it's way to Chris Groat for reduction |

Nice BIG Texas style crystals |

Copper wire inserted in a hole doesn't work too well as a seed |

5-20-07 Sneak Preview

I was in my studio about 4:00 pm. The kiln was at 1005C on the controlled cool down segment. I realized I'd be burning my fingers late tonight unloading if it kept going and seeing the other 3 people on my firing comparison just turn there kilns off after the crystal soaks, I killed the power by putting it in IDLE. At 6:30 pm it had cooled to 450C - a rate of 222C (432F) per hour. The pieces look OK.

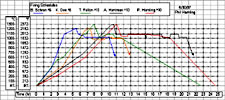

Comparison of firing schedules supplied by several contributors to the Crystalline Glaze Forum (revised 5-30-07).

I now think:

|

I can significantly increase the rate of my firing without suffering adverse effects. I followed Ilsley's recommendations on heat up when I established the program. It has served me well in that I have had no pieces blow up or self destruct, but appears much more conservative than others. |

I had a brain fart when I programmed my cool down from peak at 500C/hr. I was thinking about the heating rate and didn't want to program up ramps at the fastest rate possible in order to minimize the times the elements were "full on" so as not to stress them more than I had to and get the longest life. This is not an issue on cooling and if I cooled as fast as possible I may get less glaze in the catchers and get more to stick on the pots. |

5-19-07 16th Firing Setup

|

Today's notebook pages |

Avril, Is this light rutile? |

Kind of tight! |

|

|

|

|

Colorants in today's firing include CuCO3, NiCO3, CoCO3, MnO2 and Nd2O3. | ||

5-17-07 15th Firing Results

5-16-07 Sneak Preview 370°C

Interesting nucleation from seeding on 3 pieces.

Nickel on the bowl seeded by Mickey Mouse. I had this one mounted on the catcher before I realized I can soak the urine salts out of the pieces.

5-15-07 15th Firing Setup

3% CuCO3 in 8% rutile base and 2 1/2% NiCO3 w/ .4% titania base. Some pieces seeded with zinc oxide / silica paste filled 1/16"dia. x 1/16" deep hole.

5-14-07 See before and after...... Post Fire Reduction by Chris Groat

5-11-07

5-10-07 Clay Comparison

.jpg)