|

Fallonatortm |

Zinc Silicate Crystalline Glaze Pottery A chronicle of my recent progress and a way for me to keep it straight in my head! 2-5-11 |

|

Fallonator

Products Handmade in the USA by §Terry Fallon. |

The

Fallonator Fully automatic electric reduction kiln. |

Fallonator Add On Kit Convert your electric kiln to include reduction firing. |

More Fallonator Products To make high temp reduction life easier. |

Reduction Is No Fuss With Us!

The Fallonatortm

Fully automatic electric

reduction kiln.

Dr. Arnie Benton's Fallonator

On January 24, 2011 Hans-Joachim Wehnert wrote:

Hello Phil,

I was surfing in the internet and found your pages and wonderful examples of your work.

To introduce myself I have to say that I am residing in Germany, worked for IBM

nearly all my life and now I am retired. Over the past ten years I tried to

learn more about ceramics and glazes. So today I am an excited hobby potter.

Since three years I am working with crystal glazes and also tried to investigate

the theory behind the practical usage.

I just would like to know what is the Fallonator? I understood it is an

electric kiln for reduction firing. Is there some more detail available in terms

of description? Is the kiln available in Europe as well?

Thanks for taking the time to read and maybe to answer my question.

Best regards

Hans

On January 27, 2011 I replied:

Hans,

I am glad you found my page and it is of some value to you. Besides it being "A

chronicle of my recent progress and a way for me to keep it straight in my

head!" it has aided in the development of some tremendous relationships with

people (both amateur and professional) involved in crystalline glazed ceramics

over the last several years.

The Fallonator is essentially a typical electric kiln with some "beefed up" features (heavy gauge elements, higher temperature - lower porosity brick than normal, SSR's rather than mechanical relays, etc.) and a "revolutionary " reduction atmosphere generation system which delivers carbon monoxide derived from propane gas to the kiln and controls the amount of reduction with an oxygen sensor based feedback loop wired directly into, and controlled by, the kilns temperature programmer / controller.

It was developed by Terry Fallon. I do not know if an overall description of the "Fallonator " exists, but don't want to speak for Terry. I have copied him on this e-mail hoping he will reply.

I believe Terry has commitments to make "add on units" which will allow for the conversion of existing kilns and possibly has clients in Europe. Personally I think doing business with someone like you in Germany should be no big deal as we (ZIRCAR Ceramics, Inc.) do it all the time.

I enjoy the opportunity to correspond with you and look forward to more in the

future.

Phil Hamling

That same day Terry replied to Hans:

Hans,

Phil said it quite accurately. Its like a computer controlled gas kiln, but uses electricity for the heat. The kiln is built to the same foot print as hobby built kilns so all your existing kiln furniture fits inside. These kilns have volumes of 3, 5, 7, and 10 cubic feet and come as 8,10 and 12 sided round top loaders.

For a comparison I will use a copper red glaze firing in a 12 foot gas kiln. This gas kiln takes 10 to 12 hours to to get to cone 10 (1285°c) and is under reduction for 6 to 8 hours. It uses 21 pounds of propane and requires constant adjustment of the primary air and damper settings. Cost of firings are in the $19 to $22 range.

To fire a copper red stoneware glaze in a 7 cubic foot Fallonator kiln takes 6 hours to get to cone 10 (1285°c ) is in reduction for 2.5 to 3 hours, uses 1.5 grams of propane per minute. The total of 270 grams of propane (at $2.20 per 465grams ) consumed costs only $1.28. After adding the cost of the electricity ($5.10) the entire reduction firing costs $6.52.

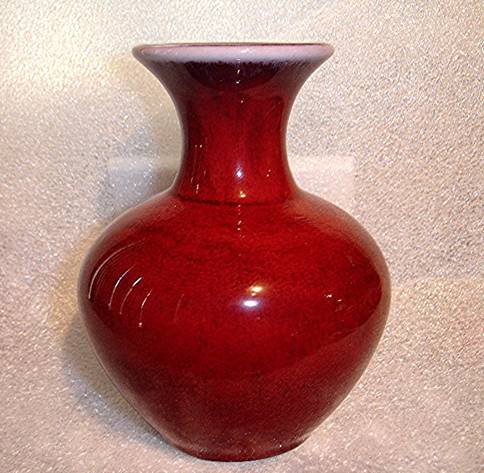

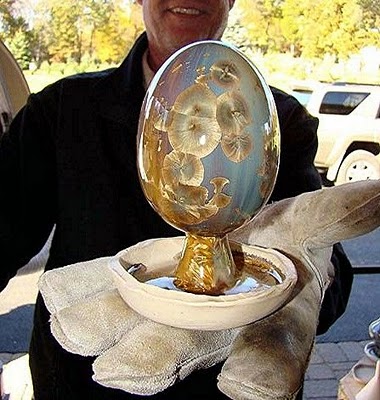

Here are 2 Copper Reds fired in my Fallonator

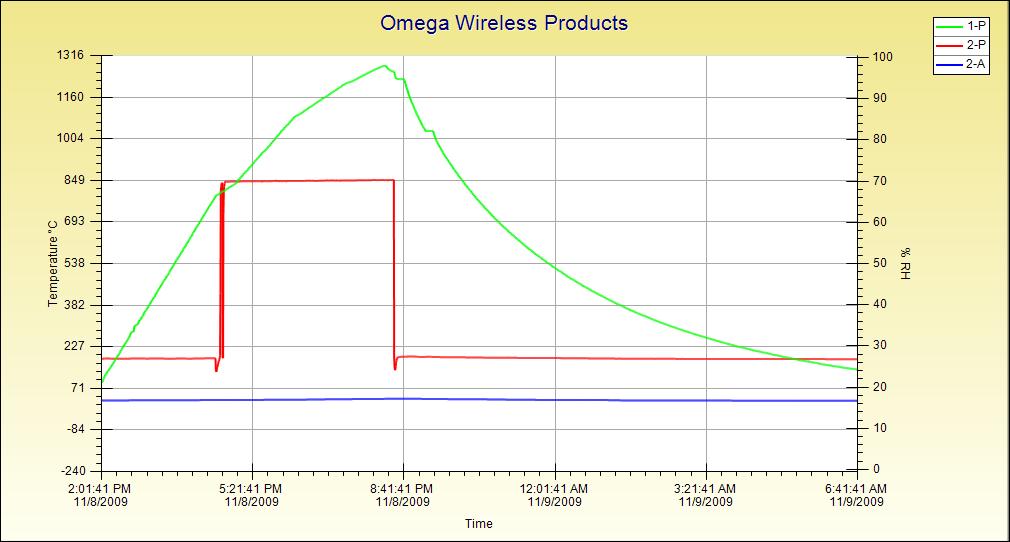

Wireless data recording of the temperature and reduction level on the same graph in real time is possible. Below you can see the firing cycle used to make these pieces. The green line is temperature (scale on the left) and the red line is reduction level (scale on right - even though it says %RH).

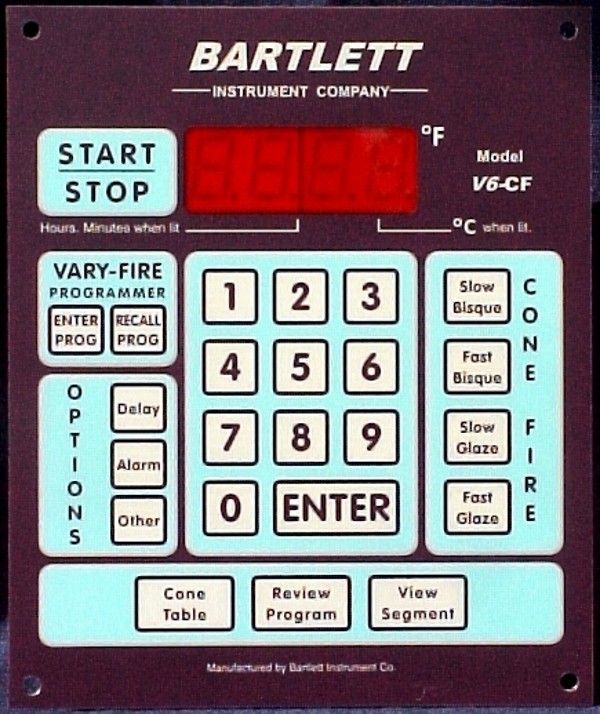

I think the packaging of the completed unit is nice to look at.

Not to mention the cost of gas piping and the space to put an ugly propane tank in the back yard. I build these to use disposable 1 lb. propane bottles that connect to the small brass regulator valve in the front.The firing cost analysis used a price of $2.25 for propane

The controller allows you to set the desired ramp and reduction schedule, press the start button and walk away. This gives you time to do things other than babysitting a gas kiln.

The front panel comes in blue too.

§terry

On January 29, 2011 Terry wrote:

The Fallonator- Reductionator- cone11 Kiln

The Fallonator is essentially a typical electric kiln with some "BEEFED UP"

features (heavy gauge elements, higher temperature - lower porosity brick than

normal.

SSR\'s high power control panel, rather than 20 amp mechanical relays, etc.)

It is "revolutionary " a Reduction Atmosphere Generation System which delivers

carbon monoxide derived from propane gas to the kiln.

It controls the amount of reduction with an oxygen sensor based feedback loop

wired directly into, and controlled by, the kilns temperature programmer /

controller.

It was developed by years of field testing in the hands professional and amateur

potters

Hand made in the USA.

“You know it will work for You”

Fallonator Kiln with Euclid’s Exclusive Halo Lid

Fallonator Kiln with Euclid’s Exclusive Halo Lid comes in

blue too.

$12,000.00 Includes free shipping to most of the USA

Optional Kiln shells:

L&L eQuad-Pro Production Kilns

L&L JH Series Crystalline Kilns

L&L eQuad Fallonator Shown here with the optional

secondary venting system.

What can You expect when you open the lid of the

Fallonator-Reductionator kiln in the morning after an Automatic Hands off Firing

while you slumber in your comfortable bed.

All these Colors in the same firing very little cross

contamination of glazes.

Want to look to see if you know someone who has seen it

work?

http://www.puttgarden.com/crystal/w.../attendees.html

Phil Hamling

376 County Route 1

Warwick, NY, USA 10990