|

Fallonatortm Add on Kit |

Zinc Silicate Crystalline Glaze Pottery A chronicle of my recent progress and a way for me to keep it straight in my head! 2-5-11 |

|

Fallonator

Products Handmade in the USA by §Terry Fallon. |

The

Fallonator Fully automatic electric reduction kiln. |

Fallonator Add On Kit Convert your electric kiln to include reduction firing. |

More Fallonator Products To make high temp reduction life easier. |

Reduction Is No Fuss With Us!

Fallonatortm Add On Kit

Convert your

electric kiln to include reduction firing.

On January 21, 2011 Terry Fallon wrote:

I’ve been asked to make some Gas Add-On-Kits. Thanks to those that have used the

prototypes over the last few years, I feel confident the design is ready for

more people to try reduction firings in their electric kilns.

Is there enough interest to make building them worthwhile? If you are interested

in one of these kits please let me know. I am hopeful to fine 10 people wanting

to give it a try.

After answers from many people Terry, on that same day wrote:

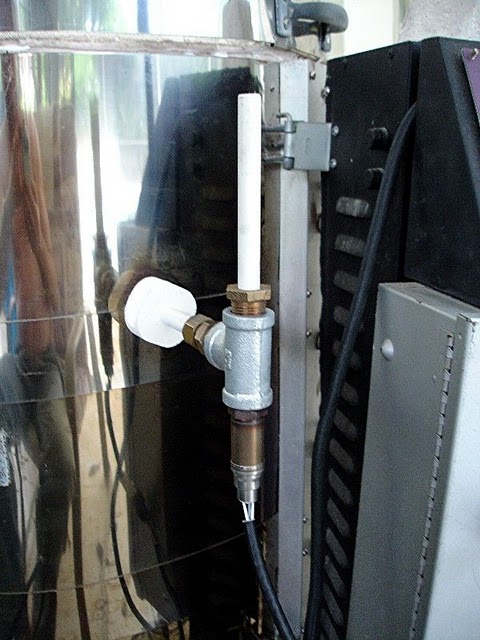

The Fallonator Gas-Add-On-Kit.....It’s design is to be installed without any modifications to the kiln.

The burner sits inside the kiln, and is feed through the bottom peephole.

The O2 sensor port is placed into the top peephole.

The gas feed and the O2 sensor connect to the controller

and, you are ready to do your first reduction firings.

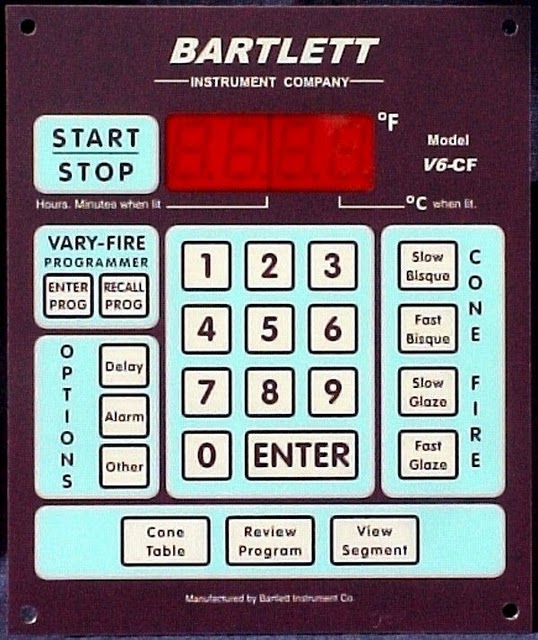

For complete automation the Add-On-kit can be controlled

by a Special Bartlett Kiln Controller made for Fallonator, some existing V6-CF

Kiln Controller can be updated with Fallonator software.

Special T/C’s too, if you want the ultimate in control

On January 25, 2011 Avi Harriman wrote:

I use a Skutt KM1227 (rated to ^8) with a custom

controller modified by Terry Fallon (blue box). The controller has:

· 3 Zone control

· Type S thermocouples

· Solid state/variable power relays

· Custom programming to turn the custom made gas controller (grey box) or fan on

and off by segment. The gas controller was also made by Terry Fallon.

The gas controller works in the following manner:

1. The gas controller is turned on and off by program segment by the white power

cord which is connected to the blue kiln controller.

2. The gas controller is fed propane from a 5 gallon tank through the grey line

at the bottom of the box.

3. The gas is split out to the high and low pressure valves (red and black

knobs) used to control the amount of gas needed for reduction.

4. The Gas gauge displays the amount of gas going into the kiln at the high and

low settings.

5. Gas enters the kiln through the gas/air mixer in the bottom peephole. The

gas/air mixer is attached to a burner assembly inside the kiln.

6. The black display in the center of the box is the computer that controls the

amount of gas that is fed into the kiln. The desired level of reduction is

entered onto the display. The actual reduction level is also displayed.

7. The computer reads the O2 sensor (white and gold device in the top peephole).

If the reduction level is lower than the desired it activates the high pressure

gas valve which sends gas out the black pipe on the bottom of the box to the

gas/air mixer. If the reduction level is higher than the desired reduction level

the low pressure valve is activated. As the firing proceeds the reduction level

evens out and is automatically maintained at the desired level.

At the Symposium I only brought the grey gas controller

and turned it on and off manually. I only did post fire reductions (1500º -

1200º) at the symposium. In our studio we do both high-fire and post fire

reductions. I have done many Post Fire and Hi-Fire firings as well as my

"normal" ^11 oxidation firings. I am a Happy Camper.

On February 1, 2011 Terry wrote:

This maybe a chance to have a piece of history.

This is the master model of the

“Fallonator Gas-Add-On-Kit” Model: G-AOK (The label states) serial number... #1.

It will be used to make all the other G-AOK units.

Soon, I will but it up for auction on EBay to the highest bidder. It will

include documents, as to its authenticity, that this unit is serial number 1. It

is the “Master model #1” of all G-AOK units.

Phil Hamling

376 County Route 1

Warwick, NY, USA 10990