Gas Kiln O2 sensor

Looking for a competitive price on a O2 sensor for you Gas Kiln or Raku kiln.

Don’t want to spend $ 1,200.00 not even $500

How about one with a replaceable Oxygen sensor.

Direct scale reading, no charts

Temperature independent, no adjusting for kiln temperature

Hi and low limit alarms

2 outputs relays 5amp at 240vac, can be use to open the damper or increase or decrease gas pressure using a solenoid gas valve.

The Fallonator O2 Reduction-Tattletale

Complete units Start at $450.00 hand made in the USA

New replacement Oxygen Sensor, ( not rebuilt or reconditioned )

Only $75

Interested

§terry

Tdfallon at Comcast dot Net

SPECIFICATIONS

Inputs:, Fallonator Oxygen Sensor

Display: Two 4-digit, 7 segment 6.35 mm H (25") LEDs (PV: red, SV: green)

Resolution: 1.0, ( 100 levels of reduction )

Accuracy: ±0.25% span, ±1 least significant digit

Supply Voltage: 100 to 240 Vac, 50/60 Hz

Power Consumption: 5 VA max

Operating Temperature: 2500°F - 1370°C

Memory Backup: Non-volatile memory

Control Output Ratings:

Relay: SPST, 5A @ 250 Vac resistive

Voltage Pulse: 14 V, 10 to -20% (max 40 mA)

Current: 4 to 20 mA

Alarms: SPST, 3A @ 250 Vac

Communication: RS485 MODBUS A-5-11/RTU communication protocol

Weight: 456 g (16.8 oz)

I was asked if the Fallonator Add-On-Kit would work in garbage can reduction kilns. I’m sorry, but the answer is no. The Add-On-Kits are for electric kilns.

I feel that these entry-level type kilns offer a taste of what reduction can do, but how dose the average Joe gauge the heat using a weed burner as the heat source? This pyrometer does the trick.

I am working on getting these reprogrammed for type “S” T/C’s as a pet project.

But I can let a few go for $ 80.00 as type "K"

On January 26, 2011 Bill Campbell wrote:

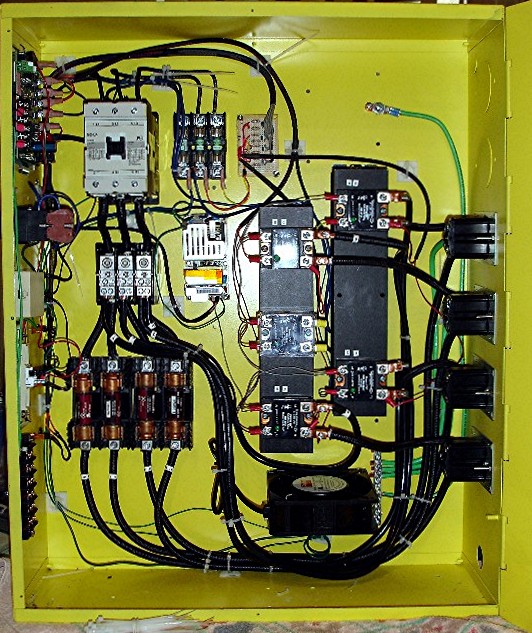

I installed a controller on my L&L kiln that Terry Fallon built for me a year ago last October.

I have had several people ask me about what I thought about the controller, but I put them off. I had been saying that I had not had the controller on my kiln long enough to really give that report.

It has been well over a year since I installed the controller on my kiln, and I am ready to report on its operation.

I fire this kiln at least three times a week to cone 11.

It has not needed any new elements and has not slowed down as kilns do when they need new elements. The elements are all standing vertically like fresh elements do.

The controller has worked flawlessly from the time that I plugged it.

I have five more L&L kilns that have magnetic relays in their control boxes, and I fire them the same way.

I plan on replacing the elements about three times a year .

The advantage has been not having to replace as many elements, and I have not lost any pottery because the kiln has lost an element, or gotten slow,

because the elements were at the end of their useful life.

I had L&L make me similar controller systems for two new kilns that they made for me. It is too early to give a report one way or another on them. They seem to be doing well, however.