.

11-12-08 I haven't

been able to spend any meaningful time in the studio recently but

here's a collection of interesting photos.

|

|

|

|

|

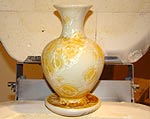

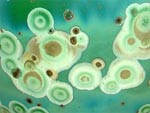

An array of

crystalline glazed pottery. |

Bella's about had it

with the political season. |

Posin' before the

last football game of the season. |

|

|

|

Kat's 10th

grade class photo. |

|

The gas pipe line (30"

dia.) is coming through. |

The tools for a 4" dia" line are

much smaller. |

Ginger ran over one of the poles

at the end of the driveway with her Camaro. We put it back up with her

name on it hoping she'll pay more attention in the future. |

11-7-08 I ran into

some old friends the other day and told them about the

Crystalline Glaze Forum. They were all ears. Then I started describing

all the people I've met and great times we've had. When I told them about

this guy in western New York State whose studio is in a geodesic dome they

loaded up and drove away chanting "We're off to see the Wizard, the

wonderful Wizard of Koz". Here's a look at them driving down Pennsylvania

Avenue.

11-6-08

Someone e-mailed me referencing my web page and asking questions about using

a cone 6 kiln for firing crystals. I inadvertently deleted it before

responding. If you read this can you re-send it? I'm happy to reply.

|

October 28, 2008 |

October 27, 2008 |

|

Well it certainly has been

an interesting day. I got a look at the 88th firing, have

pictures of some new work by Diane (not Creber), found that the Hoppa has a

mother lode of zincite and almost got banned from the Forum for life for

bringing up politics. I'll just have to get the political thing out of my

system elsewhere.

|

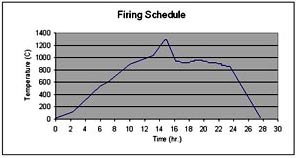

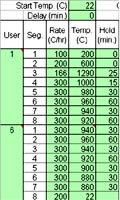

88th Firing

Results

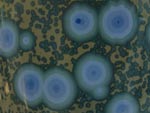

I was playing with my clear

base with 2% titania, 4% copper carbonate, a fraction of cobalt carbonate

and up to 5% Zircopax. I'm going have to sit with my notebook and see what

it all means. I do think I will use a different schedule on the next loads.

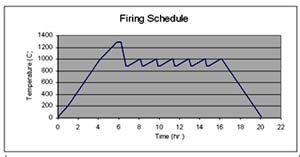

This one has 3 crash cools to ~850°C followed by gradual climbs to 1080°C.

The crashes do give a sharp delineation between segments of the program but

seem to nucleate way too many crystals

|

|

|

|

|

I'm starting to get it

together to make the plaster models for casting some Christmas tree

ornaments. |

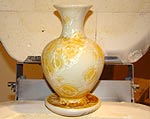

Chattered Vase by

Diane Luedemann.

Click

here for a plate |

Click

here for more

pics of the Hoppa's zincite |

October 25, 2008

Talk about jonesing! This

is my first firing in 34 days. I finally got to spend an afternoon in the

studio thanks to a rainy afternoon now that Crystalline Spectrum show,

all those pesky home emergencies and the lawn care season are over. It

should be smooth sailing for a while even though I still have to figure out

who to vote for. It's gonna' be a tough choice.

The Grasshopper asked me

about seeding. Well....he wrote "Do you know a lot about seeding? If so,

fill me in."

|

|

|

|

|

"I can't say I know a lot, but here's

what I've been doing." |

I made a particle size reducing gizmo to

get small pieces of zincite.............. |

........and use the tip of a pencil to

pick up a small dot of glue. |

Then get a small zincite crystal, ~ the

size of a pencil point, and put it on the pot. |

|

|

|

|

|

Some times it sticks to

the pot easily, other times I have to roll the pencil to get it off. |

Kat liked this action shot of me in my

patriotic suspenders the best. |

I've been doing a bunch of pots at the

same time. |

And I'm not sure what else to say about

it. |

Well........................(Should I use more .....s Mr

Wizard?).............I can say:

-Seeding helps maximize the

number of crystals which grew throughout the full range of the crystal

growth portion of the firing cycle.

-Very small pieces of

zincite can nucleate crystals.

-If the pieces of zincite

are too large you get bumps on the finished piece and often get those "ice

cream cone", or "pointy leaf" shaped crystals.

-Fa showed us how to

impress larger pieces of zincite in leather hard pots, but I don't like this

method as much because it made those funky pointy bottom shaped crystals.

October 16, 2008 Mysterio Unveiled!

|

I'm sure everyone

remembers how, about a year ago, an electric heating element expert

named Mysterio appeared on the Forum.

I always wondered who

is this person. Now I know. While worshipping on the porcelain throne

I came across this in National Geographic magazine.

Now I wonder where

did a Chilean professional wrestler learn so much about electric

heating elements? |

October 15, 2008

..............................An Historic

Perspective.............................

October 12, 2008 I haven't

been able to spend much time in the studio but have been able to do some

striking at 815°C (1500°F). Well I guess that's what you call it. I heated

400°C per hour to 815°C then held for 1/2 hour.

|

|

|

|

Copper in the

background went to tan brick mud but the white streaks may give a clue

about how to get dark crystals on a white background. |

Striking made the pale

blue on cream background darken and lets you see it through the

crystals. |

|

|

|

|

NFU before and after.

There is a little bubbling on the bottom. |

Nickel and copper with

no titania didn't do much when struck. |

More work to glaze from

Andy Boswell. |

Other Recent Distractions

|

|

|

|

|

A glorious fall day in

the yard. |

When you don't have a

stunt double you have to do the stinky jobs yourself. |

The Black Nights vs Eastern Michigan

at West Point |

The Millennium Pipeline is coming

through with a 30" line from somewhere near the Wizard towards NYC. |

October 9, 2008 Photos from

the Crystalline Spectrum thanks to Rod and Denise Simair.

|

|

|

|

Bill Schran and me |

|

Dick White's Pizza Oven |

October 1, 2008

Glaze

Catcher Removal Notes

September 28, 2008

September 26 to 28, 2008

CRYSTALLINE SPECTRUM

September 23, 2008

CRYSTALLINE SPECTRUM Update

Click here for my page

|

I got some shots from Dick White late last night showing the gallery almost

set up. Click on the picture, or

here, for a sneek

preview.

Yo Hoppa! I saw this logo on a piece of turf equipment and thought of you.

|

|

September 22, 2008

|

|

|

|

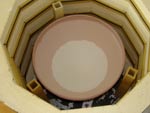

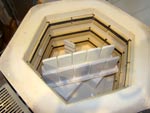

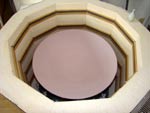

| 86th

Firing Results |

87th Firing Setup |

These pieces came out much

better in that the crystals are much larger. There still isn't enough

background though. I guess I should have put on even more glaze. There

really wasn't that much more that showed up in the glazecatchers.

I am re-re-re-re-firing

some of these in the 87th firing. I mixed a batch of 4% titania

base and added 5% CMC to make a thick paste. I gobbed as much on as I

thought would stay, kept track of how much weight of glaze I added this time

and put them on extra catchers.

September 20, 2008

|

|

86th Firing Setup

This is another refire. I added a

layer of 8% rutile base to 2 pieces and a mixture of 8% rutile and 8%

titania to the others.

I've slowed down the cooling rate

from top end from 800 to 200°C/hr. |

|

CRYSTALLINE SPECTRUM Update

Click here for my page

The gallery being set up for the show. Bill Schran is moving

so fast you can't even see him in the photo.

I do think I spot my pieces as well

as work from Bill Campbell, Ginny Conrow, Jamie (The Wizard of Clay) Kozlowski

and Robert Hessler.

Regarding my presentation on heating element design, I'll be scrambling to

button it down early this week.

September 19, 2008 85th

Firing Results: Refire of 84th Firing. I didn't add any

additional glaze to these pieces before the refire.

Just call her Krystal Kat,

striking a Heisman Trophy pose.

|

|

|

| 9-18-08 84th

Firing Results |

9-17-08 Test Fire Re-Fire

Re-Fire Result |

September 16, 2008

|

|

|

| 84th Firing

Setup |

Test Fire Re-Fire Re-Fire |

Test Fire Re-Fire Results |

September 15, 2008

September 14, 2008

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

83rd Firing

Setup |

Test Fire |

September 11, 2008 I can't

believe it's been 7 years already!

|

God

Bless America

NEVER

FORGET

9-11-01 |

|

|

|

82nd Firing Result - Sneak Preview @ 265°C |

September 10, 2008

82nd Firing

Setup - I glazed the first large form I made with .30 g/sq.in. glaze

loading and put it in the kiln with my extended lid on. I don't think there

is any risk of this lid popping open during firing. I hit the start button

and ran (crawled) to bed. I will see the results late 9-11-08.

81st Firing

Results - Having the lid firmly closed seems to be the key. Both cone packs

had cone 11 touching and the glazes came out as expected.

September 9, 2008

When I got there this

morning the unit was at 1269ºC on its way to 1290ºC.

Just looking in the studio door I could see the lid was propped up 1/4" to

1/2" and leaking heat like crazy. I pushed the lid back down and saw the

temperature climb. The program calls for a rate of rise of 185ºC

/ hr with a 20 minute hold. When it reached temperature I noticed the 2 ^9's

were just beginning to bend. After 10 minutes worth of soak ^10 was almost

touching and ^11 was on it's way down. I see these cones fall pretty

quickly. I never watched them before. I have no doubt ^11 will be touching

when I get to check it tonight.

Most likely what

happened in the previous firing is that the lid was propped open even more

and it did take longer to get to top temperature (even it it was just by 20

minutes I can see how it would make a difference). This would explain why

the room was so darned hot (100ºF) which I've never seen

before

|

|

|

|

|

Ah Ha! When I got to the studio this

morning I saw the kiln's lid wasn't closed very well. |

81st Firing Setup: I

added more glaze to an already fired pieces and set cones in front of

each peep hole |

Test Fire Re-Fire: It looks like I

have a few more pieces to torture in the Avinator in Alexandria, Va. at

the end of the month. |

In chasing what may have

happened I got input from the likes of William Melstrom, Avi Harrman, John

Tiltion, Steve Lewicki, Rob Battey and Dave Bartlett. Suggestions included:

1) check the program, 2) inspect the elements, 3) clean the thermocouple

connections, 4) verify various controller settings and 5) be there to

witness what is happening when it reaches top end.

I did all these things.When

I removed the tc extension wire and cleaned the ends with a Scotch Brite pad

I didn't see much if any corrosion.

Mr Wizard.....Thank you so

much for the input. After loading the kiln with a reglazed piece and cone

paks I set the delay timer to 4 hours so I could be there when it hit top

end this morning.

September 7, 2008

80th Firing Result - WTF?????

I thought this was going to a rather mundane firing. It didn't turn out that

way. I had a re-fire, 2 pieces with NFU at a low loading (~.35 g / sq. in.)

and one piece with NFU + 1/2% cobalt carbonate, which should have yielded

pieces with 1 1/2" to 2" dia. crystals. When I first peeked in I saw very

few smallish crystals - not what I was expecting. It looked like an

overfiring condition, but I have limited experience.

After closer examination I

saw that ^11 had slumped well beyond where it had in the past (^11

touching). The first photo above shows ^'s 9, 10 & 11 from this firing in

front and typical cones from previous firings in the rear. It looks more

like ^13 to ^14 to me.

I'm in a quandry as to what

to do to get back to the normal ^11 touching situation I've seen in the

past. I checked the program and saw that nothing had changed. Is it a

thermocouple degradation thing? Are they in need of replacement? I would

expect platinum Rhodium thermocouples to last a very long time at this

temperature. Is it just a "computer thing" and will rebooting the unit set

it straight? I have many more pieces I was going to put this this routine

firing, but don't want to screw them up and am not quite sure what to do.

Doll Test Firing Result -

Well there certainly is some green showing but the pieces are all fish

scaled. Even with a 30 minute hold at 1290ºC ^11

only came down to ~3 o'clock. I added another layer of uncolored 8% titania

glaze to the pieces when they were still above 100ºC

(it sticks prettty well) and refired it with a 35 minutes soak at the top

end.

|

Result |

|

Re-Firing |

|

|

|

September 6, 2008

|

80th

Firing Setup |

Doll Test Firing |

|

|

A few more NFU pieces plus a refire.

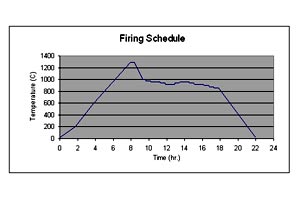

I'm using the schedule of

4-27-08 except I've sped up the first 3 segments |

|

2 refires plus a new one. All have

some copper in hopes of having some nice stuff to reduce at Bill

Schran's. |

September 4, 2008

|

|

|

|

The second photo has a Cameron and Farley, plus 2 Snairs added for

scale |

September 1, 2008 Labor

Day Holiday Weekend

August 30, 2008

August 26, 2008

August 23, 2008

One more try!

|

|

|

|

|

|

I'm giving this one

more shot. This is the fourth one so far (there are two other variations

still waiting for the finishing touches).

In this attempt I

stripped out about half the clay on the upper 2/3rds of the

slabs to thin the wall and lighten it up plus left some extra material

to make the base wider. I like the transition from the top into the foot

better than in the previous one. I hope that by today the base has

firmed up enough that I can remove the stamp and make a low profile

glaze catcher.

|

Notes on Bill Schran's

show

THE CRYSTALLINE SPECTRUM: A JOURNEY FROM STUDENT TO MASTER

.........

|

|

|

|

|

|

My current studio

mate! |

It was glorious out

in the yard today. The sun had that intensity which makes fresh

cut grass glow. |

The Grasshopper's new stamp. Nice stuff

Nathan! |

August 20, 2008

August 17, 2008

August 17, 2008

|

|

|

|

|

|

79th firing setup.

Mostly NFU at .35

g/sq. in. loading |

Trying to make a

little less of a "Pegleg Pete" this time. |

Kat & Dillon's camouflage paint job

on the fountain controls. |

Robert Hessler's Studio Sale |

Increasing the hold time to

30 minutes brought ^11 close to touching, but there's nothing to write home

about in terms of the glaze. I added 2 1/2 coats of fresh glaze and am

firing them for the third time.

August 16, 2008

I increased the Doll's hold

time at 1290C to 30 minutes in the hopes of getting ^11 touching in this

test firing. Maybe that will help with fewer crystals.

August 13, 2008........Totally Off Topic

|

A contractor friend of mine has had

a job building a Buddhist Temple recently. Pictured are 2

"doohickeys" he'll be installing soon. |

|

August 10, 2008

I have to tell you.....This is probably the most

rewarding slab built form I've made yet. I really enjoyed the process and

like the shape too. I'm sure it breaks many of the "Art" rules, but who

cares. I like it. It's about 18 inches tall and I can't wait to see some

nice crystalline rings on it. I plan to use NFU at a low loading rate where

I'll see minimal glaze run off and have built a glaze catcher kind of

doohickey into the base.

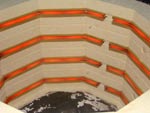

This is

the kiln I recently bought from a friend for $120. He bought it off the

sidewalk from a guy who was trying to get. Although it has strictly manual

control I think it will be useful for use as a reduction torture machine. It

looks like it is circa the 1970's to me. I'll have to check with Steve

Lewicki to find out if the serial number helps date it. I'll bet its older

than the Grasshopper.

The elements are in great

shape and look like they have seen heat < 1/2 dozen times. The brick between

sections was a little chewed up but I applied some ZIRCAR AX Moldable and

CTP-1 Paper between the joints and they look to be sealed up right nice!

August 6, 2008

|

|

|

|

|

Nothing better than

a

fresh hair cut. |

It's amazing how much the weeping willows have recovered from their June

1st

pruning. |

Don't tell anyone but Bella has a foot fetish.

|

Tales from the Pickle

Jar

This test involved using

the same glaze*, on the same clay, in the same firing at different loading

rates. (*OK, it had been aged 6, 23 and 65 days in a jar before I used

it.) It appears aging (at least for this time period) makes no difference in

the reaction of the glaze, but glaze thickness does not only with the color

of the background but with the shape and color of the crystals. Note how

little runoff there was from the pots with the lower glaze loadings.

August 5, 2008

|

|

|

|

|

78th Firing Results. It looks like I

was successful bracketing the looks I've seen come out of NFU (Clear

Base with 4% Rutile and 3% Red Copper Oxide). It's look at this low

temperature is very dependent on glaze thickness. |

I

kind of like the way this test came out. Trying to approximate a

Mankameyer firing, all I had time for was to press the START button and

walk away. |

Ray

and Mathew Boswell at Tuesday night class.

|

August 3, 2008

|

|

|

|

|

78th firing setup. This load is

mainly loading variations of NFU glaze stored in the pickle jars for

various lengths of time. |

Test firing of 8% titania glaze with

.4% cobalt carbonate. |

I had to straighten the place up. |

August 2, 2008

|

|

|

|

|

Giffin Grip, marble

chuck, clay, pot to trim and Avi's scrap computer drive bearing makes

trimming this slender bottle easier. |

I had to add a wad

of clay to this thin bottomed pot to get by stamp on it. Also I've taken

to dating the pieces |

My latest piece.

Thanks Ray Boswell. I think the lines are getting better, but I still

feel clueless |

It looks like

Gorilla Glue will work for bonding layers of foam insulation for making

the next set of slab built pot. |

I have used Gorilla glue for years but never

read the directions. It says to moisten one surface with water which causes

the glue to foam. It works like a charm and makes the glue foam and harden

in 4 hours. Being water based it doesn't dissolve the blue foam like Super

77 spray adhesive or other petroleum based material do. I'm going to put a

bunch of material together an machine the forms on a CNC router this time.

July 30, 2008

- 77th Firing Results

July 26, 2008

- 77th Firing

********

Crystalline Glaze Quiz

Name the 5 frequent

Crystalline Glaze Forum visitors who created these.

July 20, 2008

|

|

|

|

|

I guess I didn't have these joints,

which split open in bisque, joined very well. |

Building glaze catchers for these

pieces which bisqued OK. |

1 1/4 year old Fallon Classic with a

healthy mold coating. |

Mixed leaf lettuce salad anyone?

Photo shot in the black dirt fields of Pine Island. |

Fishing this weekend in NY's Thousand

Islands

Phil won the bet with the

6#, 32" Northern Pike he took off Scow Island with Singer Castle on Dark

Island visible across the shipping channel.

July 16, 2008

76th Firing Results

July 14, 2008

76th Firing Setup

July 13, 2008

|

|

|

|

75th Firing Setup |

|

74th Firing Results |

The results of the 74th

firing were poor (from a visual sense) to say the least. The

crystals were quite bland and there was virtually no run off in the catcher.

So I quickly loaded some more glaze on the bowl getting the loading up to

.40 g/sq.in. On the positive side I did learn that

a loading of .25 g of solids per sq. in of area just isn't enough. Also

there were many, many pinholes. Then Mr. Turner told me, in an attempt to

save electricity $, he bisqued these pieces to ^06 using the "Slow Glaze"

cycle which runs much faster than the bisque cycles. My guess is the clay

wasn't hot enough long enough to complete its dehydroxylation and off

gassing.

July 12, 2008

|

|

|

|

74th Firing Setup |

These have been final shaped and

burnished. The prismatic one has been a bear as the flat faces have

bowed concave out as it dries. I've reshaped it 3X and finally

resorted to covering it where it wants to dry first. |

The 17 1/2"

dia. David Turner bowl in

this firing has the glaze (NFU) brushed as thin as I could while getting a

real even single coat. It worked out to be ~.25 g of solids per sq. in of

area. This is about 1/2 the loading of

June 16th's firing - a lighter

loading than I expected. It is reproducible, and I can add more and keep

track of exactly how much I have on as I'm glazing.

I expect this

will give a look similar to the results of my 68th firing and will see for

sure tonight (7-13-08). I plan to explore loadings in between .25 and .5 g

solids per sq. in.

|

|

|

|

|

The kitchen is coming along real

nice. We're hoping to pick out the granite counter tops this week. John

Welch (www.finekitchenandbath.com) has been doing a fantastic job and is a pleasure to work with,

plus I think he's more anal than I am, if that's possible! |

Patti modeling the spring loaded

wiffle ball antennae earmuffs I made to add a little comedy to lawn

mowing. |

This year's blueberry crop is

looking real good! |

July 5, 2008

July 4, 2008

June 29, 2008

June 29, 2008

June 27, 2008

|

|

|

| Test Firing of a pot

glazed the same as in the previous firing. |

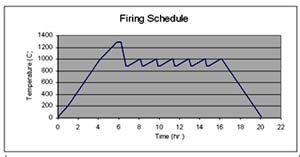

I'm trying this low temp repeating

cycle schedule with my fingers crossed hoping the crashes aren't so

severe as to nucleate too many crystals. |

1 coat of fiberglass resin started

dissolving the foam. Bummer! |

June 24, 2008

David, I'd say

tonight's smoking was quite nice indeed. You really pulled out all the rings

nicely. I wonder if a little iron would give some yellow highlights?

June 23, 2008

|

|

|

|

Shaped with wood putty and then 2

coats of latex paint. |

|

Before and after 3X reduction by David Turner. |

June 16, 2008

73rd

Firing Results

I'm still trying to get a

good handle on the relationship of crystal growth to glaze thickness for

this glaze when fired in the low temperature range (860C to 1000C). I

brushed one heavy coat of the pudding consistency glaze on each piece with

and additional 1 1/2" band on top.

For the 2 pieces in the

right photo I measured the amount of glaze I added and estimated their

surface area to determine the loading rate. They had 0.51 and 0.46 g solids

/ sq. in. of surface. All these have the characteristic look of some of the

first NFU pieces I made. I can, and will, apply the glaze more thinly (0.4 g

/ in. sq.) on future pieces to hopefully get back to the "explosive" crystal

growth I saw before.

Regarding the 2 pieces in

the right photo, the one on the left had the 2 1/2 week old glaze and the

one on the right had it from a new batch. I don't think the aged stuff

worked as well.

June 15, 2008 Happy

Father's Day!

|

|

|

|

|

A 2 1/2 week old "pickle jar" of

NFU. |

73rd Firing Setup

Thanks

for the photos, Kat. |

Another beauty by

Glenn & Keith. |

June 13, 2008

I had the good

fortune of spending 4 days with John Mankameyer at his home and studio in

Miles City, Montana.

He's located

deep in the heart of cattle country! On the trail Lewis and Clark followed

when exploring in the early 1800's. Near the site of Custer's Last Stand by

the Little Big Horn.

John has been

making crystalline glazed porcelain since the mid 1970's. After years of

doing the show circuit in Northern California now he's retired and still

actively experimenting with these glazes and his unique twist to them. John

has a motto posted on his PC which reminds him of his charter (I guess)

which reads: "I am trying to do more than make a pot with colored blotches

on it"

June 7, 2008

June 5, 2008

|

|

|

|

| A fantastic

birthday present from Avril Farley. |

|

|

|

|

|

David Turner:

Potter, Carpenter, Fawn Master? |

|

My latest 2 pieces

from Tuesday night class. |

May 31, 2008 72nd

Firing Results

May 29, 2008 71st

Firing Results, 12" Diameter X 14 1/2" Tall

May 27, 2008

May 26, 2008

David Turner's latest big

bowl is on the bottom. It is all NFU except for the inside bottom which is

8% rutile base. The top shelf is all NFU too. I gave the pieces a heavy coat

of glaze right around the top lips this time to try and get more of the

action I've seen around the bottoms further up the pots. The little guys are

on their second firing with a little more glaze.

|

|

|

|

Half a day on the lawn, the other

half in the studio. It doesn't get much better than this. Low 80's with

a light breeze and all the freedoms afforded us by this great country.

Happy Memorial Day! |

Oh, to be an 18 year old Bad Ass

again! |

|

On Memorial Day, the flag should be hung at

half-staff until noon, when it should be raised to the top of the staff. |

May 25, 2008

May 23, 2008

Replacing elements. I used

the the "B Tank" torch to bend the leads around the posts as well as bend

the coils in the corners to get them to lay in the slots. I should have

stretched them to about 74" length first to put them in compression a

little. I'm sure they'll settle in after the first firing.

May 20, 2008 69th

Firing Results

When I got

home from the rock pile last night the kiln was still going through the last

holds. It did shut off and was cooling, but by "Pumpkin Time" it was still

500°C.

I was able to peek and saw it was not good. The crystals looked nice, but

the pot had collapsed. I knew those 2 real wet rings on the outside, when I

glazed the inside, were the sign of doom!

I did check into what capability my

controller has, but unfortunately I didn't order the amp check feature. I

plan to do a continuity and resistance check before the next firing, but I

have to admit I loaded a bisque this morning.

May 19, 2008

At 8:00am this morning the cycle should have been 1/2 way through the 9

hours worth of holds. It hadn't even reached

top end

of 1290°C

yet. The programmer was calling for

1257°C

but the chamber temperature was only 1240°C.

I added some more insulation to the lid and left for work. Then at 11:00am I

returned and saw it had topped out and was at 1143°C

on its way down to the first hold at 1000°C.

It appears to be 8 hours behind schedule.

May 18, 2008

It looks like my elements

are about done. I was expecting to see an over firing condition when they

got to the point of not having enough "snot" to get there (resistance too

high) in the programmed time, resulting in a heck of a lot more heat work

happening as it slowly, I mean slowly, crept up to top temperature. It

looks to me like they are running out of gas as the furnace hit somewhere

between ^12 and ^13. I didn't really pay attention but seem to recall the

programmer said this cycle took 32 or 33 hours - about 10 hours longer than

it should have.

I decided to fire the 69th

anyway and watch it (as much as I could). I turned on the 16 segment feature

(see

firing schedule of April 27, 2008), pressed the start button about 6pm

and noticed at about 9:30pm the programmer was calling for 500°

but the chamber temperature was 495°C.

After Dance Party Note: We had about 250+

kids here for a party which ran from ~10:15pm (after the dance) until 3:30am

(when I started asking people to leave). It was in the barn, the house, the

yard and the Christmas Tree Field. It was like Woodstock. Driving rain all

night, and mud all around the bonfire. The kids seemed oblivious too it and

I imagine had a great time. I have spoken with no angry parents, neighbors,

police or attorneys either.

May 14, 2008 68th Firing

Results

The big one and little one

in the front are first fires with one even coat (I'm happy to see) of "thick

shake" glaze. A little more glaze on top and I think they would have the

exaggerated growth low temperature crystals all over them. I haven't seen

these crystals grow this large before. There was very little run off to the

catchers, but some. Next trial I will add a little more glaze right around the

top.

May 12, 2008

|

68th Firing

Setup

The big pot and a small one were

glazed with one coat of the "thick shake" glaze shown below. This

was what was used on the "1, 2, 3, 4 and 5 coats..." tile in the last

firing. At this consistency the glaze doesn't de-water fast, and I'm

hoping allowed me to get a thin even coat and will result in the dual

color "low temp" crystals again. |

|

|

|

NFU except

1, 1 3/4, 2 1/2, 3 1/4 and 4% rutile. Things seem to be on target with

the 4% rutile currently in NFU. |

1, 2, 3, 4

and 5 coats of NFU. I think this test demonstrates that a thin glaze

layer is key to the formation and growth of crystals at these low

temperatures. |

May 11, 2008

|

|

|

|

|

Norma, I like! |

|

Sneak Preview, 300°C |

May 10, 2008

This load is all re-fires.

I mixed more NFU with 4% CMC. The thick shake consistency made it easy to

apply a reasonable coat which stayed put. There is also a test tile strip

with 1, 2, 3, 4 and 5 coats of NFU to see if I can get a clearer picture of

the relationship of low temperature crystal growth habit to glaze thickness.

There is another with 1, 1 3/4, 2 1/2, 3 1/4 and 4% rutile.

May 8, 2008

|

|

|

|

Glenn Woods and Keith

Herbrand's work continues to amaze me. Glenn wrote "..we won first

place in ceramics at a smaller local show but we were up against some

really awesome work so were felt honored to pull this one off." I'm

thinking ...ART... no Mr. Wizard? |

I came home from work to a green

carpeted with cherry blossoms tonight. |

.

This is the firing schedule

for the last firing. Many people have asked about it so I put it on my

firing schedules page as well as here.

Jesse Hull wrote "You said,

"It seems the thickness of this glaze at these low temperatures has a major

impact on whether these crystals will form and grow." If you're going to

compare glaze thickness -or anything else for that matter- shouldn't you use

similar, if not identical, forms? The form on the left is a far cry from the

one on the right... going from nearly flat to nearly vertical within your

testing scheme. And the one in the middle has a neck which holds glaze that

eventually runs onto the shoulder (replacing the glaze which is lost there),

while neither of the others do."

Using identical forms and

measured amounts of glaze for a glaze thickness comparison certainly would

be a good way to quantify the situation. Maybe besides cutting into the

piece to measure the glaze thickness there is an optical method to use.

I think these recent pots

are examples of ones with glaze on the thin side and ones which have this

type of crystal. My observation about "...the thickness of this glaze at

these low temperatures..." is based:

1)

On seeing the pot on the right with broadly separating rings on its top

which formed at temperatures below 1000°C.

And on the shoulder where it is thicker, and the high temperature crystals

(1050°C

to 1080°C)

grow

quickly

there is little separation between the low temperature bands.

1)

On seeing the pot on the right with broadly separating rings on its top

which formed at temperatures below 1000°C.

And on the shoulder where it is thicker, and the high temperature crystals

(1050°C

to 1080°C)

grow

quickly

there is little separation between the low temperature bands.

2) This glaze appears green when thick and

tending towards aqua when thin. This thick - thin is based on believing I

know how much I've brushed on.

3)

Seeing these greenish pieces

not having formed crystals at these low temperatures and knowing I brushed

on a very heavy application of glaze.

3)

Seeing these greenish pieces

not having formed crystals at these low temperatures and knowing I brushed

on a very heavy application of glaze.

4) Re-firing the piece, seeing the glaze

flow off the pot and accumulate in the catcher, the color change towards

aqua and crystals forming.

I

think the piece on the right exhibits a greener color on the bottom where

the glaze is thick and has small crystals with more of a traditional look,

and tends toward aqua color on the top where the glaze is thin and has

larger, faster growing crystals on top where the glaze is thin.

I

think the piece on the right exhibits a greener color on the bottom where

the glaze is thick and has small crystals with more of a traditional look,

and tends toward aqua color on the top where the glaze is thin and has

larger, faster growing crystals on top where the glaze is thin.

It's interesting to note though that I may

say fast or slow, but the "fast" growing ones here in this "thin" glaze at

these low temperatures (860°C

to 1000°C)

only grow at a rate of

~1inch in 9 hours. That should be enough time to grow 6" diameter crystals

at higher temperatures (1080°C)

May 7, 2008 66th Firing Results

(Probably the lightest load since firing #9)

May 6, 2008 (My 52nd

Birthday)

May 5, 2008 65th Firing Results

These were

fired with 1050°C

and 1080°C

holds. Click the photos for more info.

May 4, 2008 65th Firing Setup

|

|

|

|

|

I'm trying to reproduce firings

#63 and #64, except I think I actually put the frit in this time. |

Tests strips with copper and

cobalt + manganese with from 0% to 10% titania. |

Silicon Carbide abrasive applied

under copper carbonate containing glaze. |

.

Thanks Kat!

Page: Current 12

11

10 9

8

7 6

5

4 3

2

1

Back to Crystalline Glaze Information Page