b

12-31-09 Last day of the year! It'll be time for Page 9 once

I fill in this puppy and we move into 2010!

What would be better than to finish out 2009 with photos of

some work by Diane Creber.

Fallonating outside in the winter is a bummer as is doing it

inside with the door slightly up. Finally I "hole sawed" a hole for the

exhaust and machined an interlocking set of aluminum flanges, which I'll

Gorilla Glue in place once it gets warmer. I plan to make a quick release

plug to fill the hole when its not in use. Maybe I'll make a crystalline

glazed tile (~3 1/4" dia.) to mount on the outside of the plug so it looks

even more interesting from the outside (unless a friend already has one).

12-30-09

|

|

|

|

|

I can see myself doing more of this

glaze and will probably tweak things to get fewer larger crystals. |

A Dr Arnie #1 glaze piece only slightly

blushed on top after striking 1 hr at 1500C. |

Doohickeys affixed to the top of diamond

sawn and lapped ornaments with epoxy. |

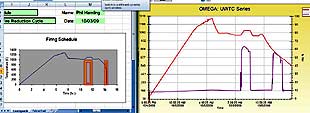

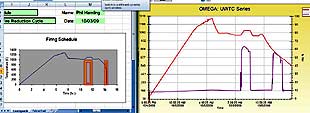

12-29-09 I reprogrammed the Doll cycle to include an

initial short soak at 1000C

followed by a "longish" slow ramp from 1120C to 1080C.

Pieces above right with Dr. Arnie's 644-F20 base with

1) CuCO3 - 2%, CoCO3 - .3% and SnO2 -

5% after oxidation firing in the e23s and 2) "Arnie's Metallic

White": Fe2O3 - 2%, CoCO3 - .2% and TiO2

- 6% after high temperature reduction firing in the Fallonator.

12-28-09

|

|

Results from yesterday's firings. |

|

| Fallonator |

e23s |

Doll Firing |

|

|

|

|

| Arnie's 644 base with

CuCO3, CoCO3 and SnO2 before and

after PFR. |

F413 base w/ 2% copper carbonate and

1/2% cobalt carbonate |

Tonight's Doll Firing |

12-27-09 Dr Arnie came and we spent the whole day glazing

ornaments. He brought 2 uncolored pre-mixed F413 and F644 bases. His 644-F20

base contains 644 - 46.5, 3134 - 2.6, Zn -20.0, Si - 30.0, Molochite - 0.4,

Li - 1.0 and VGum Cer - 1.0

We mixed 2 finished glazes from his and some from what I had prepared the

day before.

12-26-09

Dr. Arnie Benton is coming tomorrow. I mixed up 11 different

glazes, some based on F413 and others on F644.

12-25-09

12-24-09

12-23-09

I finally got to fire the bowl

Diane Luedemann dropped off

before the Symposium (2 center photos). I've

never been much for the "puddle of glaze in the bottom" effect before, but

think this one came out nice.

12-21-09 Once I started getting

crystals I began to tweak the firing cycle to get bigger ones and in my last

several firings was getting decent size ones with background showing.

As an added bonus I think I learned on pieces with clear

crystalline glaze on the top and red on the bottom that if the crystalline

glaze overlaps the red it just sort of washes over the surface. If it is the

other way around, red lapping up and over the clear that the clear glaze,

being much more fluid, flows down under the red an creates streamers - a

much more interesting effect.

I mixed new glaze and found I had the same poor result.

Swimming upstream I sensed the 3110 frit in my container didn't look right.

Finally I changed it, mixed new glaze and started getting decent results.

I had a heck of a time getting any decent results, The clear

crystalline glaze I was using not melting and was coming out with a bubbled

matt look whether it was on the top or bottom of the piece. It's a good

thing I have a small test kiln or I'd be making a lot of junk.

12-15-09 I can't believe its been

over 2 weeks since I posted anything!

|

|

|

|

|

Tonight's firing - Holly's

Red on thick with a cap of clear crystalline glaze. |

USS Alaska

departing Port Canaveral earlier today.

Another

photo.

And yet

another. |

Kat found a site which

takes distorted photos through the web cam on the laptop. (www.cameroid.com) |

Work in Process - Body of a

harp by Andreas Widhalm cast using a CNC

machined 3D plaster mold. |

Last Week

11-28-09

.

|

11-26-09 |

11-25-09 |

|

|

|

|

| I finally got all my photos and

pages from the

Symposium processed. |

|

First ornament firing result. |

Casting some more. |

b

| 11-24-09 |

11-16-09 |

11-15-09 |

|

|

|

|

| First ornament firing. |

A look inside Phil Morgan's wood kiln

Saturday night. |

SS129 Atlantis Launch 11-16-09 |

Casting a few. |

.

11-10-09

11-7-09

|

|

|

|

|

More slip cast ornaments. |

Jerry sized this bad boy perfectly.

It's the last piece of bisque from the Electric Reduction Symposium.

It's time to start glazing. |

The football season

ended last night at the NYS Section 9 Class AA

finals. |

11-5-09

11-4-09

|

|

|

|

|

Crystal close up from the Pottery

Gangsta. |

The true look of Gold Stuff, by Kris

Friedrich. |

Recent Ares 1-X launch with cone

formed as it broke the sound barrier. |

10-28-09

|

|

|

|

|

Can you tell I'm a rank amateur?

Andy is going to kill me! |

Are these the same crystals seen in

aventurine glazes? |

3110 base w/ 6% copper carbonate,

.05% cobalt carbonate & 2% rutile. All first fired together. Far right

one struck at 815°C. Middle and far right with the "Childers Effect". |

|

10-26-09 |

10-25-09 |

|

|

|

|

The sun went down as the lights came up over the soccer

fields in the Town Park. |

^05 Bisque |

|

10-25-09

10-21-09

I was in the studio until 11 last night trimming pots people threw at the

symposium and will post pictures and the attendees list in the next several

days. I have some beauties!

10-18-09 Got

back from dinner with Kris, Ginny, Avi, SarahLyn, ~jesse, Terry, Cindy,

Arnie, Avril and Peter at Château Hawthorne, put some pots (thrown by

masters) in the damp box, watched the Fallonator kick into reduction (Terry

forgot to plug in the oxygen sensor......just like a plumber!) with Avi and

SarahLyn, tucked ~jesse in and am in front of the computer at 12:50am ready

to collapse. But..... here's a tease.

10-17-09 Holy

mackerel do I have some news to report about the Symposium!

We counted 52 people at the

open ceremony Friday night, each of whom had a chance to get up and tell

their story. What a magnificent happening. I bet I've taken 1000

photos so far, as did many others. The weather basically stunk (we got

snowed on!) but it didn't matter. Most times we were inside as one big happy

group of crazed crystal maniacs. It did warm up and the wind stopped tonight

for the bonfire.

The generosity of everyone

has been amazing. I'm not a real weepy kind of guy, but felt choked up a

whole bunch of times.

I'll jump on the full

report as soon as the event is over and can't wait to get to it.

10-11-09 Getting

Ready for the Show!

|

|

|

|

|

This article appeared in the 10-9-09

Warwick Advertiser |

The weather forecast looks like

we'll have the woodstove cranking! |

Many thanks to William Melstrom for

dealing with the whole tee shirt thing. It's looking like maybe they

should have been sweatshirts. |

10-5-09

FF9 Results

10-4-09

|

|

|

|

Plan (left) - Actual (right) I tried

a high fire reduction followed by a "post fire reduction" just all in

the same firing. |

I think people will be able to see

this at the end of the driveway as they drive up. |

It was a beautiful day and the

colors are coming! I hope its like this in 2 weeks. |

I got quite a bit longer

reduction in the second wave then I planned. I know the kiln can't cool

faster than about 200°C/hr

at that temperature, but proceeded to program a drop of 1000 which resulted

in an extended reduction segment.

FF8 Results (With my best

Melstrom impersonation on the right.)

.P

| 10-1-09 Fallonator

Firing #8 (FF8) Setup |

10-3-09

Homecoming at WVHS |

|

|

|

|

|

A David Turner and 2 Paul Lorbers. |

The last 2 Dr Arnies. |

Warwick Wildcats 54 -

Washingtonville Wizards 0 |

Kat's smile shines through. |

|

|

|

|

|

Carbon plug: It seems like it is right

where the vent tube exits the brick and alumina goes to brass. |

After Cleaning |

VEEGUM CER adds an

amazing brushabilty to the glaze

Data Sheet |

September 28, 2009

September 27, 2009

|

|

|

|

|

Holly McKeen sent a beautiful piece

(<3" tall?) and a bag of dry glaze to use on pieces during the

Symposium. I can't wait to dig in. |

The leaves are just beginning to

turn here. They should be primo come CGS time! |

More test soldiers all formed,

seeded and drying. |

Paul Lorber dropped off

some pieces and glaze this week too.

September 22, 2009

Fallonator Firing #7 Results

September 21, 2009

|

The computer graph from

the previous firing was just plain old weird. It looked like the

reduction level didn't get up above ~750mV. That's the main reason I set

this one so I could experience it in real time.

In this firing I found that rather than going up to the set point of

855mV and controlling it again only got up to ~750mV. The gas seemed to

be flowing. I turned the pressure up and could hear more flow (the tank

actually frosted) but there was no real change in the meter. Terry

thinks maybe the poop chute is blocked and I'll need to do the old

Roto-Rooter job. Stay tuned. |

|

September 20, 2009

September 19, 2009

105th Firing Results

Epsom Salt Test

What exactly does adding 2% Epsom salts to a glaze do? I know Ginny Conrow

is a proponent of it and recently wrote "I

just don't understand WHY one uses CMC, which seems to make for all sorts of

problems (sieving, deteriorating the glaze, etc) when a bit of Epsom Salts

keeps the glaze in suspension without these problems." I've found that

adding CMC helps hold glazes with high drying shrinkage on pots and

lengthens the time available to brush out the glaze. Dick White wrote

"The CMC makes it soooo much easier to brush the additional thick layers and

get it on relatively smoothly." I'm with Dick on this one. I found in the

glaze NFU, where a thin even layer of glaze is critical, that adding 4% CMC

makes a thick paste which brushes out evenly very far and even. Ginny sprays

so I'm not sure what she sees in it and had to take a look for myself.

Feri Halmos taught me that adding 1 drop per liter of concentrated Epsom

salt solution aids the dispersion of glaze ingredients. I have been doing

this ever since. I mixed up some Gold stuff with .7 g water per g of solids

and 1drop concentrated Epsom salt (CES). Then added 2% Epsom salt to 1/2 of

it and let it sit overnight.

|

After 18 hours the sample with 1 drop CES showed no

obvious settling while the one with 2% Epsom salts had ~1/4" of

water on top. |

|

| |

|

|

|

|

|

|

The sample with 1 drop CES was quite

fluid but did "split" a little on the top surface. |

The sample with 2% Epsom salt was

very thick and creamy after decanting the water. |

They left distinctly different

appearances on the walls of the glasses. |

|

I brushed these 2 samples

on bowls from Dr. Arnie. I was targeting a 0.5g / sq. in. loading so as to

not get a lake of runoff in the bottom and tried to apply it evenly.

The sample with 1 drop CES

was very watery and brushed out quite thin. I was able to go over the

surface 3X before reaching the target loading. I did notice the material

seemed to settle within itself getting quite thick on the bottom as I worked

it.

The sample with 2% Epsom

salt was quite thick and creamy. Although I was sure it would go on nice and

smooth it de-watered almost instantly on contact not allowing me to brush it

out smooth. I was hard pressed to get the target loading with 2 coats it

went on so thick. I guess this would be a plus when spraying - fast

de-watering - but not when brushing.

I will wait for the results

of the next Fallonator firing to see if the 2% salt made a difference in the

outcome of the glaze.

|

|

September 18, 2009

105th Firing Setup

|

|

I have been spending so much

time playing with the Fallonator I've haven't fired my kiln in a while.

This is the first firing in air in ~3 months.

I

took another whack at Terry's "James Bond" glazes. I dropped the peak

temperature to 1250°C (2282°F) while firing in air. |

|

More flux tests. Fresh off

the hernia operation table it was tough to do much more than think about

stuff. I was curious about how glaze reacts with alumina hydrate and silica

so I set up another test like I did with kaolin and alumina.

|

|

|

|

|

Alumina hydrate (Al(OH)3)

on the left, silica on the right. |

Al(OH)3

with just enough water to wet turns into a thick gel. |

After a short time at just above

100°C it is showing major shrinkage cracks. |

The next day both showed severe

reaction with the glaze. |

September 14, 2009

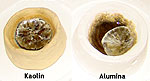

Kaolin appears to resist the glaze better than alumina. It was wet by the

glaze as was alumina, but the glaze seems to have wicked in to the alumina

cup and attacked it faster then kaolin.

September 13, 2009 I know

the proof is in the puddin', but I put together two little desert cups. One

of kaolin the other of alumina. Each has a ball of Gold Stuff glaze and is

going through a typical crystalline firing just to see what happens.

Kaolin or Alumina? I

started using alumina as a separator layer between pots and catchers but

switched to kaolin. I found it releases better. Alumina seems to be wet by

the glaze whereas kaolin does not.

Page: Current 12

11

10 9

8

7 6

5

4 3

2

1

Back to Crystalline Glaze Information Page

![]()