December 28, 2007

46th Firing Results

This firing turned in a day

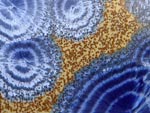

and I like the way the rings came out, especially on Steve Klinsky's vase.

The crystals have quite a bit of depth and a more natural look to them.

|

|

|

|

|

These are the largest glaze catchers

I've thrown yet. |

I attribute the range of colors in

this load to Nick's need of deep blue and §'s

comment that I should fire more colors. |

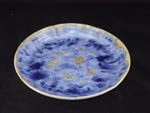

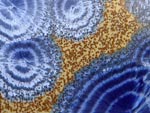

Nick's deep blue (seeded) plate came

out real nice. It was my titania base with 3% each

CoCO3, Fe2O3 and MnO2. |

Not everything is "Peaches

and Cream" though. I noticed the stained engobe was cracking off the largest

piece on the top shelf when I loaded it. I must have applied it too dry.

Well anyway it seems to have self destructed in several places during the

firing. I can see it in the bucket of Holly's loader now!

I am having

fits with this borrowed

camera. Steve's vase really begs for closer photographic attention, just not

with this camera. I'm either going to get mine back from repair soon or will

splurge and just go out and buy the real deal.

Firing Setup

|

|

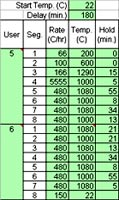

I increased

the heating rate to allow the original 11 hour heat up to occur in 7 1/2

hours, the hold time of the first 1080C hold to 2 hours and each

temperatures hold from 5 to 15 minutes to show more distinction between

rings. |

|

December 27, 2007

45th Firing Results

Nick Conklin

stopped by with his camera and took these pictures for me.

December 27, 2007

45th Firing

Without my

camera I feel like I need the Wizard to come and do shadow puppets like he

did at Krystallos 2007. My kiln

is cooling at ~300C and the load looks pretty interesting.

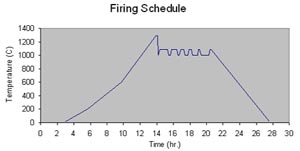

(I'll unload it in the morning). I used this schedule,

http://www.puttgarden.com/crystal/tech/firing graph/12-25-07/graph.jpg,

which has a lot of time at (relatively) low temperatures and made some nice

light colored action around the outsides of the crystals.

Steve Klinksky's piece with 2 1/2% copper

carbonate in my 8% titania base glaze on it is probably the nicest of the

bunch. There is quite a bit of dark secondary action in the background as

opposed to one of my grolleg pieces which doesn't have much.

My first stab at dark blue

was a bomb as was the piece with 2% tin oxide and .4% copper carbonate. Just

a bomb in that the composition needs to be adjusted to get (more) crystals.

The tin has an interesting effect on the glaze. I'm sure Terry can do

something to it in the Fallonator.

The next time I use this schedule I'm going

to lengthen the holds to get bigger crystals with more separation between

the rings.

I borrowed a camera and took some sneak

preview shots, but I won't be able to get them off the camera until

tomorrow, and by that time I'll shoot the finished product.

December 23, 2007

I think I have a

great new tool just in time for Christmas. It's an Excel spreadsheet which

generates firing curves on the fly. Input Rate, Temp. and Hold info, just

like you do in the Bartlett controller, and it builds the firing curve right

in front of your eyes. This ought to make it real easy to work out a firing

schedule and see the curves in the future. I think it's going to be like

reading music.

Avi gave me the great idea

of cataloging my firings this way. Check out this

page as I build it.

Send me one

of your firing schedules and a picture of the crystals it makes and I'll put

it up.

December 22, 2007

|

|

I actually had a lot of fun putting

this stuff together, especially the page on the left (even if they are

all recycled photos).

And thanks to Ferenc Halmos for the

beautiful Hungarian winter landscape shots.

Enough's enough though. Tomorrow I'm

looking forward to getting my hands back in the stuff! |

|

|

Fibonacci Sequence Firing Results |

Feri's Hungarian Winter Landscape Photos |

December 20, 2007

Bummer....Bummer....Bummer....Bummer....Bummer....Bummer....Bummer....Bummer....Bummer

My camera

crapped out and started taking pictures that look like the Northern Lights.

It turns out this is due to a defect in the electronics. Apparently this

problem runs rampant through Sony's cameras and camcorders. They have

agreed, as a result of a class action law suit settlement, to repair it it

at their expense. I am waiting for a UPS label to include when I send it off

to Laredo Texas for repair. It could be months before it comes back. I will

need to get a different camera to keep the photos flowing, but will probably

be down for a while.

December 17, 2007

|

|

|

Dr. Deborah Bernstein's first load of

"Let's Make a Deal" bisque. She comes from the world of "Other

Ceramics" but you watch as she gets bit by the Crystalline Bug!

Check out her previous work

here. |

December 17, 2007

44th Firing Results

December 16, 2007

Funky Weather....Even the sculpture would rather be inside.

December 15, 2007

44th Firing Setup

|

|

I'm finally firing

those lidded pieces I made oh-so-long ago. I'm trying the

Fibonacci Sequence I described on 12-9-07

and the large "Fallon Stilts" for some of the lids. |

|

Rearranging the Studio

I moved things

around a little to get more of a flow to things and end the feeling that I'm

working out of a heap. Now there is a home for green ware, bisque waiting

for catchers and pieces ready to glaze. Also I don't have to walk around the

table every time I want to mix a new glaze.

December 9, 2007

Fibonacci Sequence

In my Crystalline Glaze

Forum Post 3518 I wrote: "....have inspired me to try to incorporate the

Golden Section (or Golden Ratio) in the progression of rings (in) my glazes.

.......for a more "natural" looking ring transition."

I plan to combine these

soaks in my next firing. The high temperature hold (1080 C) soak times

decrease according to the Fibonacci Sequence 55, 34, 21, 13, 8 & 5 while

alternating with low temperature hold (1000 C) soak times which increase

according to the reverse sequence 5, 8, 13, 21, 34 & 55.

December 8, 2007 43rd

Firing Results

December 7, 2007

December 4, 2007

December 3, 2007

43rd Firing Setup

December 3, 2007

42nd Firing Results

.

|

|

|

|

Glaze Adjustments - Results |

December 1, 2007

42nd Firing

Setup

.

|

|

|

|

Glaze Adjustments - I'm trying to find out what it takes to get

glazes which allow the body stains to show through, and am trying to

apply some of The Wizard's suggestions. |

A friend gave me a great gloss

white glaze which survives the crystalline firing schedule without

going matt. The gloss black on Fallon Classic is another story. |

.

.

|

|

|

|

|

I thought I was using Zochem 160

zinc oxide. Thanks to John Tilton I looked closer and saw it was

actually Zoco 103. |

My next bag is Denzox. I think

I'll go shopping for more Zoco 103. |

November 29, 2007

41st Firing Results

I know the Wizard doesn't like the dragon droppings that 8% titania leaves

in a crystalline glaze, but I kind of like it on the 1/2% cobalt carbonate +

2% manganese dioxide colored pieces!!!!!

November 27, 2007

41st Firing

Setup

November 25, 2007

Wesleyan Potters Annual Sale

November 22, 2007

|

Happy Thanksgiving |

|

|

A line blend of base

glaze with no titanium dioxide containing 2% nickel oxide and 2 1/2% copper

carbonate gave some interesting results. I was trying to see if I could

match to colors of the top 2 pieces on this page.

http://www.vases.biz/segraves_page3.htm Copper carbonate without

titanium dioxide makes an aqua color, not green. The second from the right

is the best match, but needs to be deeper. Maybe a little titania will do

that without making the nickel turn bile colored.

| Base Glaze + |

Parts |

Base Glaze + |

|

2% Nickel Oxide |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

|

| |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

2 1/2% Copper Carbonate |

Last night I spent several

hours showing Nick how I prepare pots for glazing, including sanding and

rinsing the piece, lapping the mating surfaces of it and the catcher,

cleaning each then attaching them with glue and kaolin. We finished quite a

few.

It's been difficult to get

a decent imprint from my acrylic logo stamp when I can't get to trimming

fast enough and the piece is very dry. I can press a wad of clay on the

piece but if it's dry enough to release from the stamp it usually cracks

around the edges. If wet enough not to crack it sticks. Andy came up with

idea of machining the stamp from bisque. I tried at our normal feeds and

speeds, but found at 18,000 rpm it spit sparks and flame like one of Koz's

dragons. This one was machined at 5,000 rpm and 5 ipm feed. It's a little "chippy".

The next ones I'll do wet. I can't wait to try it.

November 15, 2007

40th Firing

Results

This is the first time I've

tried copper carbonate in a glaze with no titania or rutile. It gives quite

a different effect. As far as how I like it goes, let's say I'm still

chewing on it. I do like the way both glazes broke in the plates.

November 14, 2007

I was so fried after a long

day at work and previous night in the studio until midnight that all I could

do in class was watch Andy's 3 demos, trim the stoneware piece I threw the

week before and apply porcelain slip to it.

November 13, 2007

40th Firing

Setup

This firing includes 2 of

Norma's plates (one with NiO2, the other with CuCO3) a

piece of a dinner plate I pressed in 1979 ( with both glazes), a

current piece of mine, the 3rd firing of a Fa's workshop dog after adding

the CuCO3 glaze over

the existing 4% MnO2 over 5% erbium oxide plus test tiles

containing a 7 step line blend of the 2 glazes.

I mixed one batch of 300

grams of "Clear Base" glaze with 2% NiO2 and another with 2 1/2%

CuCO3. Literally a drop of Epsom Salt solution makes an amazing

difference in the rheology of the glaze. Without it, the glaze is thick and

doesn't move well in the blender. With it it thins right down, flows easily

and becomes much more brushable, even with uncalcined zinc oxide in the

batch.

November 10, 2007

November 10, 2007

November 7, 2007

|

|

|

|

The red flags (hopefully to keep the damn dog from

digging holes in the green) look a little like red tulips to me in the

early morning light. |

|

I made the front vase out of

stoneware and plan to apply porcelain slip. I am very happy with it and

think its beauty is a direct result of Andy's tutelage*. |

Andy Boswell is one hell of a potter

and teacher. Amazingly talented, his skills have most recently been

honed at the School of American Crafts at

RIT in Rochester, NY. You can check out more of his work at

http://www.sonofapotter.com/index.html

(* and his Dad Ray -

http://www.potteryretreat.com/) |

November 5, 2007

3 Samples of Zinc Oxide

|

Zochem P160 from Bailey Ceramics which I calcined

for 1/2 hr @ 800C. 0.8 g/cc tapped density. |

Denzox from Trinity given to me by Jan Anthony. 1.5

g/cc tapped density. |

Unknown variety of zinc oxide I purchased at Alfred

University in 1978. 1.6 g/cc tapped density. |

October 31, 2007 39th

Firing

October 27, 2007 38th Firing

October 25, 2007 37th Firing

October 23, 2007 36th Firing

These pieces were glazed with the 8% titania base

colored with 2 1/2% copper carbonate and 2% manganese dioxide + 1/2%

cobalt carbonate.

The firing cycle included a 3 hour soak at 1080C followed by 5 ups and downs

to 1000C and finally a slow ramp to, and hold at 950C.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This a catcher fell off during

glazing and broke. My repair didn't hold but the ZIRCAR Alumina

insulation sponged up a lot of glaze. |

|

Steve Klinsky's test tubes |

|

|

|

|

Setup |

At dawn the

wind picked up an the hickory leaves let loose. |

October 20, 2007

Water or

Zinc?

|

|

|

|

|

Calcined zinc oxide |

Bisque ready for glazing pieces from Chris Groat,

Steve Klinsky and Nick Conklin. |

October 6, 2007

Resolution of Water Woes?

October 2, 2007 35th Firing

Results

September 30, 2007 35th Firing

Setup

I made a few

minor changes to the firing cycle including reducing the top hold from 15

minutes to 5 to get closer to ^10 and changing the order of the rings. I

reprogrammed the 3 hour 1080°C to

happen after the 5 up and downs between 1000°C and

1080°C.

This should give me small bulls eyes inside a wide growth ring. I expect in

many places this large ring will surround many clustered bulls eyes.

The 2 glasses

and a pair of chalices have the 8% titania base with

2% manganese dioxide + 1/2% cobalt carbonate and the second pair have the

8% rutile base. I finally glazed that teapot I

made 28 years ago with gloss white on the inside and 8% rutile base on the

outside. Maybe if I suck up to § I can get him to reduce it for me so there

will be gold crystals on a streaky purple background.

34th Firing Results

All in all I'm pretty happy

with how things came out. The 3% copper carbonate + .1% cobalt

carbonate glazed vases have just a hint of blue green as I expected. The

firing seems to be reproducible even though the elements are aging. Cone 11

is touching like it did 2 firings ago. The rings look about the same.

Chris, The 2nd glass looks

just like the first from the last firing. I think the bowls foot should have

been deeper. That way I wouldn't have to grind the glaze drip off. It

doesn't look bad ground, but would be better as - is.

September 28, 2007 34th Firing

Setup

In addition to 12 test

tiles with various ^10 reduction glazes from the studio where I'm taking

throwing lessons I have some more Chris Groat pieces, plus finally one of my

own.

These are glazed with the

8% titania base with a) 1% copper carbonate + 1% red copper oxide, b) 3%

copper carbonate + .1% cobalt carbonate and c) 2% manganese dioxide +

1/2% cobalt carbonate.

I'm very interested to see

what happens to ^11 in this firing.

Page: Current 12

11

10 9

8

7 6

5

4 3

2

1

Back to Crystalline Glaze Information Page