.P

|

September 9, 2009 |

September 10, 2009 |

|

|

|

|

|

The shelves David Turner is working

on are really taking shape. |

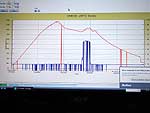

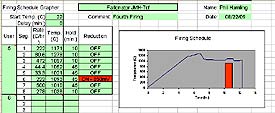

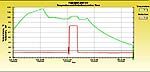

The Fallonator went through a

re-oxidation firing. The plot has a bunch of noise I hadn't seen before.

Maybe it relates to the receiver hanging on a phone jack or the computer

sitting on a cast iron pot belly stove. |

Just a little off the mark!

This is my friend Paul Tougas and

"NO TERRY!", ZIRCAR Ceramics has nothing to do with it. |

I've been

having an

interesting dialogue with Tom Turner who has been kind enough to send

some more photos and comments.

I wrote to Tom.....

Tom, I have been thinking about trying to combine copper reds and crystalline

glazes but realize I really don't know squat about the former. Can you

direct me to any good resources to enable me to bone up on copper red

basics? Check his reply at the bottom of this

page. It lead me to the article by Tom Coleman which was published back

when I was getting my BS at Alfred University.

September 7, 2009 I spoke

with Carol Levine this weekend. She is coming to the symposium. It turns out

she is retired and has been a obsessed with crystalline glaze for the last

10 years. I think she'll fit right in with the rest of the group.

September 6, 2009

|

|

|

|

|

Today's Fallonator firing has some

Gold Stuff, Fallon Gold and Brown Eyes on board. |

Giddy youth football cheerleading

coaches |

Diane Luedemann at New Paltz |

Diane wrote: "New Paltz

Show.....We were the only booth with crystals! What's happening to the

world??????"

Carol Levine contacted me

about coming to the Electric Reduction Symposium. If I have the right Carol

Levine......what an amazing person. I mean go get a degree in fine arts and

one in medical illustration, work at it for a while and then get an M.D.? She

reminds me of my youngest sister, Dr. Amy. She has a BS in Mechanical

Engineering, worked for a large furnace company for 10 years, then up and

went to medical school for her M.D.

|

September 5, 2009 |

September 6, 2009 |

|

|

|

|

|

This shelf project is really taking

shape. David got the brackets attached to the cleats and ready to go up

on the walls in the background. |

Now he's cranking! You have to see

this guy at work. |

More deer food? I hope not. |

September 4, 2009

I visited Dr. Arnie Benton yesterday and met Johna (Mrs. Benton), his

daughter Allison & guard dog "Nick". They are the nicest people! And the

pooch was a lot of fun too. (Bella went nuts smelling me when I got home.)

The Fallonator 3 is a real

lady, compared to mine. Nice sleek lines, no bands around the mid section

and built like a Brick Outhouse! We loaded for a post fire reduction cycle.

I'm looking forward to the results.

|

September 3, 2009

I have been trying to come up with a

logo for the Electric Reduction Symposium. One which says "electric

heat.....no oxygen".

Here's one possibility.

I'm thinking about having it printed

on the left breast or sleeve of tee shirts to hand out.

Maybe I'll add the words

ELECTRIC REDUCTION SYMPOSIUM in a ring around it. |

|

|

August 30, 2009

Kat is taking her first pottery class in school this year. She wanted to

"bone up" a little before the year begins. I think she may be catching the

bug.

August 29, 2009

| Dilemma Solved |

|

Gordon Czop |

Consistency Factors |

|

|

|

|

Thanks to

great input from people on the Forum I went ahead and finished off

the bottom of this piece. I took away quite a bit of material which took

"forever" using plunge depth of .010" per pass, down feed 4" per minute

(ipm) and feed rate of 10 ipm. |

Recent work with "Hydro-Carbon

Reduction" |

The Wizard (Jamie Kozlowski) says (and does) it like no one else! |

Gordon Czop wrote

"Tried the Cu Mn and Co glaze you suggested with what I call Hydro-Carbon

reduction. Still in Canada, hope to get back to attend your symposium."

August 27, 2009

I've got a

lovely marble vase from Beijing which I think will make a great mold model

for slip cast "test tiles". Using a CNC router with several different

carbide bits I freshened up the middle bottom of another piece as a test. I

also carved my insignia in it, which I intend to do on the bottom of the

vase. The problem is, is it just plain old wrong to put your mark on work

someone else started? I'm not sure how I or others feel about it.

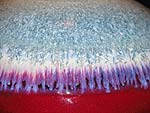

Oxblood and zinc lithium

crystal glazes with no slow cooling by Tom

Turner who "will try to bring new ones to the "seminar" (party)."

"Notice

they didn't run much." Notice Tom's coming to the party!

|

August 26, 2009

|

August 25, 2009

|

|

|

|

|

|

I found this on the cover of a

magazine in the office junk mail today. Single crystal zinc oxide? It

must be tiny (100X magnification). |

6% titanium glaze with a 4 hour soak

@ 1975°F, by Diane Luedemann, for

flowers at her daughter's "White Themed" wedding. |

Two new glazes by Terry Fallon fired

in the Fallonator 3?

"Fallon Gold" on the left & "Brown

Eyes" on the right. Terry wrote "When

in reduction one crystal darken(ed), the same growth ring on the other

lightened. " |

August 23, 2009

I still don't know what it is but think it came out sweet and like it with

a big fat candle glowing inside.

August 22, 2009

Fallonator Firing #5

August 17, 2009

Various loads of bisque from David Turner

|

August 17, 2009

First coat of polyurethane on new

shelf components.

|

August 16, 2009

Arnie,

I'll bet there were 500 kids here last night. I can't remember the

last time I was up until 2:30 am (or slept until 10:00 am). The

yard looks to be in amazing shape. I think a pack of them got up already

this morning and cleaned the hundreds (if not thousands) of empty cups and

cans strewn about.

It looks like every square foot of lawn between the barn, house and

Christmas tree field is trampled flat. It will stand back up in a few

days. Phil

|

August 15, 2009

Kat turned 16 yesterday. After

a trip to the DMV to get her permit we spent a bunch of time just

driving around (learning).

Tonight

is her sweet 16 party. DJ....... Caterers.... Bonfire...... etc. We

expect probably 300+ kids to descend on the place. It'll take days to

clean up!

Billy Idol -

Sweet 16 Charlie

Brooker on My Sweet 16 Tonight

is her sweet 16 party. DJ....... Caterers.... Bonfire...... etc. We

expect probably 300+ kids to descend on the place. It'll take days to

clean up!

Billy Idol -

Sweet 16 Charlie

Brooker on My Sweet 16 |

August 14, 2009

Way off topic but too cool to pass up. Final assembly photos of NASA's Ares

1-X Test rocket courtesy of Paul Tougas. This is "NASA's first flight test

for the agency's next-generation spacecraft and launch vehicle system...."

|

Check out

their official page. |

|

|

This photo for

scale. |

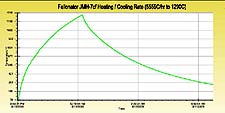

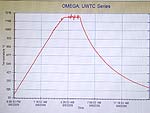

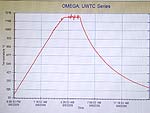

JMH-7cf Firing Info (No Load).

Avi's comment (after reading about the "5555 rate")

August 11, 2009

JMH-7cf Firing Info (No Load). Avi's comment (after reading about the

"5555 rate") supplied with the photo on the right - "It's

a runaway train!!!!! THROW THE SWITCH!!!!!"

August 10, 2009

Tonight the Fallonator is heating to

1290°C at a 5555 rate just to show what she's got. It hit 680°C after 1 hour

with current readings of 20, 18 & 18 and I hit a wall. I'll check it again

in the am.

August 8, 2009 The

Fallonator is doing a bisque (of

David Turner originals) tonight with the top and bottom

peeps out. It has seen about 3 hours of reduction so far and it's time

to run it in air to re-oxidize the elements.

|

|

|

|

The element holders

have take on a very dark color due to the reduction. |

Gourd, pumpkin and pooch. |

These shelf parts are

ready for the first coat of polyurethane having been hand sanded with

220 mesh paper, washed, dried, re-sanded and wiped down. |

It was a beautiful day to be with these

sunflowers. High 70's with low humidity!

August 6, 2009

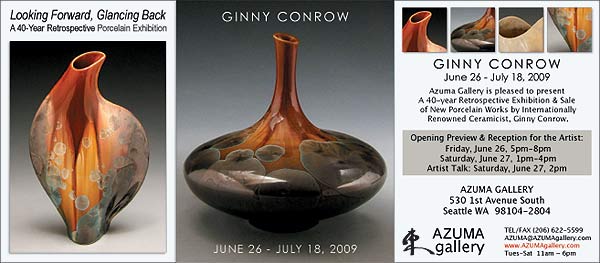

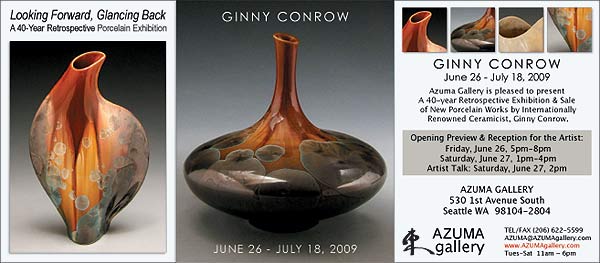

Ginny (Conrow) says "........ my

favorite tall form, was re-glazed and refired...hence the great falling

crystals! See you soon!!

Slightly Off Topic

|

|

|

|

|

View inside the main hall at

Boldt Castle on Heart Island

in The Thousand Islands. |

Kat and Shannon tying the boat to

the dock in the Thousand Islands. |

I'm finishing the

components of the brackets for a new shelf system David Turner is

building for the workshop. |

One way to precision

machine a complex ceramic fiber shape is to put it inside a box and sand

away everything outside the box. |

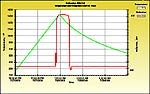

July 30, 2009

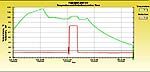

Fallonator Firing Schedules

|

High Fire Reduction

7-26-09 |

Post Fire

Reduction

7-27-09 |

|

Reduction Level

Oxygen Sensor (mV)

Light 800 to 830

Medium 831 to 859

Heavy 860 to 890

July 28, 2009 Firing F-3 Results

Post Fire Reduction

These pieces all seem to have a metallic

luster to them. They appear different in different

light...incandescent......florescent.......I'm looking forward to seeing

them in the daylight. I have no idea why the plate in the Qulin's mouth

looks to have a green background in this photo. It appears to have a

purple-red to blue luster to me.

July 27, 2009 Firing F-3 Setup.

Post Fire Reduction Firing Schedule

Firing F-2 Results

July 26, 2009 Firing F-2 Setup. It should go

into reduction automatically in the middle of the night just as I'm in the

deepest sleep. I'll get to see the graph showing the actual temperature and

reduction level in the morning before I go to work thank to the wireless

data logging system.

July 25, 2009

July 24, 2009

July 23, 2009 Terry Fallon and Dr. Arnie

Benton came for the maiden voyage of the Fallonator. It was like summer camp

for big kids.

After a whole lot of arm

twisting we were able to convince the Grasshopper to help out by glazing a

few pieces. I tell you.......all he wanted to do was play golf and talk

about motocycles!

July 22, 2009

I got the Fallonator assembled and

idling at 200F to dry for 4 hours tonight. Terry and Dr. Arnie are supposed

to come at ~10am tomorrow for the maiden voyage.

The grasshopper showed up today on his

way from Boston to Milwaukee on his new bike and is spending the night. He

says he'll stop in on the Wizard when he travels west tomorrow.

July 18, 2009

July 10, 2009

July 8, 2009

|

|

|

|

|

Clamping fixture for

welding solid terminals on double twisted leads of a heating element.

Click here for the other end. |

I've been speaking with

a company about getting them to manufacture slip cast molds from these

models. This is the information they wanted (I hope).

I've intended on doing

it myself but time has been a tough commodity to come by these days and

I'd like to have some of these to glaze during the Electric Reduction

Workshop. |

June 30, 2009

June 29, 2009

June 28, 2009

June 27, 2009

I took out the burned out element,

repaired the brick lining and replaced the element.

Tomorrow I plan to put in a

1/4" inlet in the bottom peep and exhaust tube in the lid.

|

A paste of colloidal

silica and 325 mesh alumina seemed to make a nice "caulk" type material

for filling the remaining joint outside the alumina powder layer on both

the inside and outside where the rings meet. |

|

Repaired interior prior

to a 3 hr drying segment with the bottom ring on low, before heating to

2150F with th e lid cracked and bottom peep out. Quite a bit of stinky

smoke burned out of the kiln lining. |

|

|

|

|

|

After gouging out the

rest of the "rot" I filled the larger cavities with Kaocrete HS (a 2600F

rated castable) after removing the fiber and coarse aggregate. |

With the top kiln ring

upside down I realized I still had a layer of thin RCF paper which

looked like it was acting as a carbon wick helping the brick get

dissolved. The alumina powder layer seemed unaffected. |

I was able to gouge out

most of the attacked brick, but there were still deep trails into the

seam. |

June 21, 2009

104th Firing Results

Reduction Results: I think I got an interesting glazed

piece, but did burn out an element in the process.

June 20, 2009

|

|

|

|

|

A rainy day is a good excuse to

spend some time in the studio. |

104th Firing Setup |

Doll Test Kiln Firing |

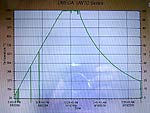

|

These are both firing the same

schedule. I pressed the start buttons at the same time and should get a

good look at how one compares to the other during firing. |

|

|

|

|

|

I felt the ceramic fiber gasketing

wasn't working as well as expected and that maybe a seal of alumina

powder between the sections would. I laid it on, nestled the next

section on and worked it side to side and front to back to seat things.

Vacuuming up the mess was the last step. |

Loaded for Post Fire Reduction. |

|

|

|

|

|

The kiln is heating through 1200F

when the first load of "Reducing Agent" is applied. |

Bomb # 2 got dropped when the kiln

hit 1500F with the power switched off. It looks like the top element is

still glowing. |

Stinky....stinky.....stinky!

It looks like the lid is the only

place the smoke was coming out. |

We've had a little moss infestation

for the last 2 years. Digging out the worst of it is a real PITA! |

|

|

|

|

|

Turf disease loves this weather. |

Newton's rings from a little

spilled gasoline flowing on the wet pavement. |

Kat is really getting the whole

"Let's bake a Cake" thing down! |

June 17, 2009

|

|

|

|

This glaze has 3% copper carbonate +

1/4% cobalt carbonate (and no titania) in it just waiting for post fire

reduction. No one is going to accuse me of lifting this form by golly

jeepers! |

What's new in the back

yard? §Terry's latest "Blue Jean on

Purple" plus some sections of old, used, brittle kiln elements as lawn

art . I mean brittle! You can snap the coils off in your hands and see

there are 4 to 5 crystallites across the section of the wire. They are

still flexible enough that they wave in the wind. If I recall this is

3.25mm APM wire wound on a 2" diameter pipe. I'm surprised to see it so

bunched up, like A-1 does when it gives it up. |

June 14, 2009

103rd Firing Results There

are definitely a few things to chase here.

June 13, 2009

103rd Firing Setup

I have the pleasure of trying a few glazes provided by Kris Friedrich

If you were a sand trap

you'd probably need a face lift after 8 years too!

June 11, 2009

Kat asked me to tell the hoppa that she found the best use of

zincite in her jewelry work.

I've got to dust that

shelf!

June 9, 2009 Around the

yard and office.

.

|

This load saw 1 hr @ 1500C

(2732F). |

June 7, 2009 Gordon

Czop...some work...and his grayling.

June 5, 2009

|

Meet Neil Casper Simak.

He's new into crystalline glazes and in deep! I've added Neil to my friend's

page.

He's going to come to the

workshop.

I am so looking forward to

the workshop in October. I figured I'll have everyone check in with Kat to

get a name tag and give me the chance to make sure I have everyone's correct

contact information and get a current photo of everyone. Kat will be playing

"Little Hostess / Photographer Girl".

|

June 1, 2009

Here's some work by Neil Simak, currently a student at Miami University in

Oxford, Ohio. He wrote "I have been using your website ...... to start

making crystalline pottery." Neil's got his own website and Forum at

www.neilsimak.com

May 31, 2009

.

Page: Current 12

11

10 9

8

7 6

5

4 3

2

1

Back to Crystalline Glaze Information Page

![]()

.jpg)